SigzenMFG ERP for manufacturing is a powerful, mobile-first solution built on ERPNext, designed specifically for line-based and multi-process medium manufacturers. It delivers real-time transparency and control over your entire production flow, enabling clear operation-wise costing and quantity tracking right from the shop floor to management dashboards. Eliminate manual errors, reduce operational costs, and accelerate your manufacturing processes with SigzenMFG — your digital partner for a data-driven factory.

Key Features

1. Deep manufacturing and ERPNext expertise

Built on ERPNext Manufacturing best practices

SigzenMFG is designed on top of the standard ERPNext Manufacturing module, extended with advanced subcontracting, job card, and QC capabilities tailored to real-world shop floor scenarios.

Industry-focused process design

Workflows for discrete, process, and job-shop environments are modeled to handle multi-step operations, partial completions, rework, and subcontracting without breaking standard ERPNext logic.

Certified ERPNext partner implementation

Sigzen Technologies delivers end-to-end consulting, implementation, and support, ensuring SigzenMFG is configured to your products, BOM structures, and costing requirements.

2. Advanced subcontracting and job card control

Consolidated subcontracting orders

Create a single subcontracting order for multiple job cards, with automatic material transfers to job workers and auto-completion of job cards and stock entries on receipt.

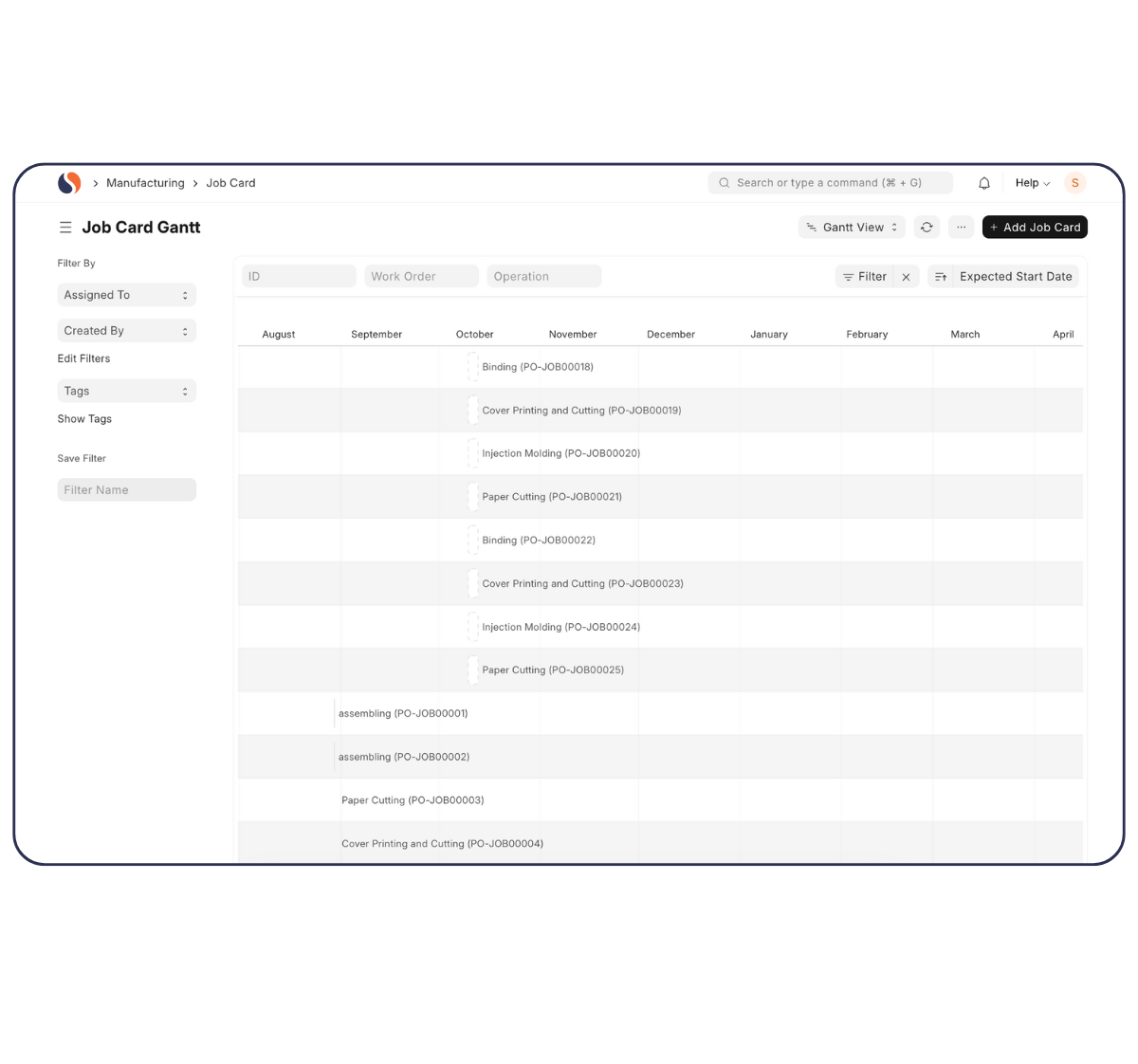

Dynamic job progression and partial outputs

Track scrap and partial completions in real time, trigger subsequent job cards after QC approval of semi-finished output, and maintain accurate costing for partial quantities.

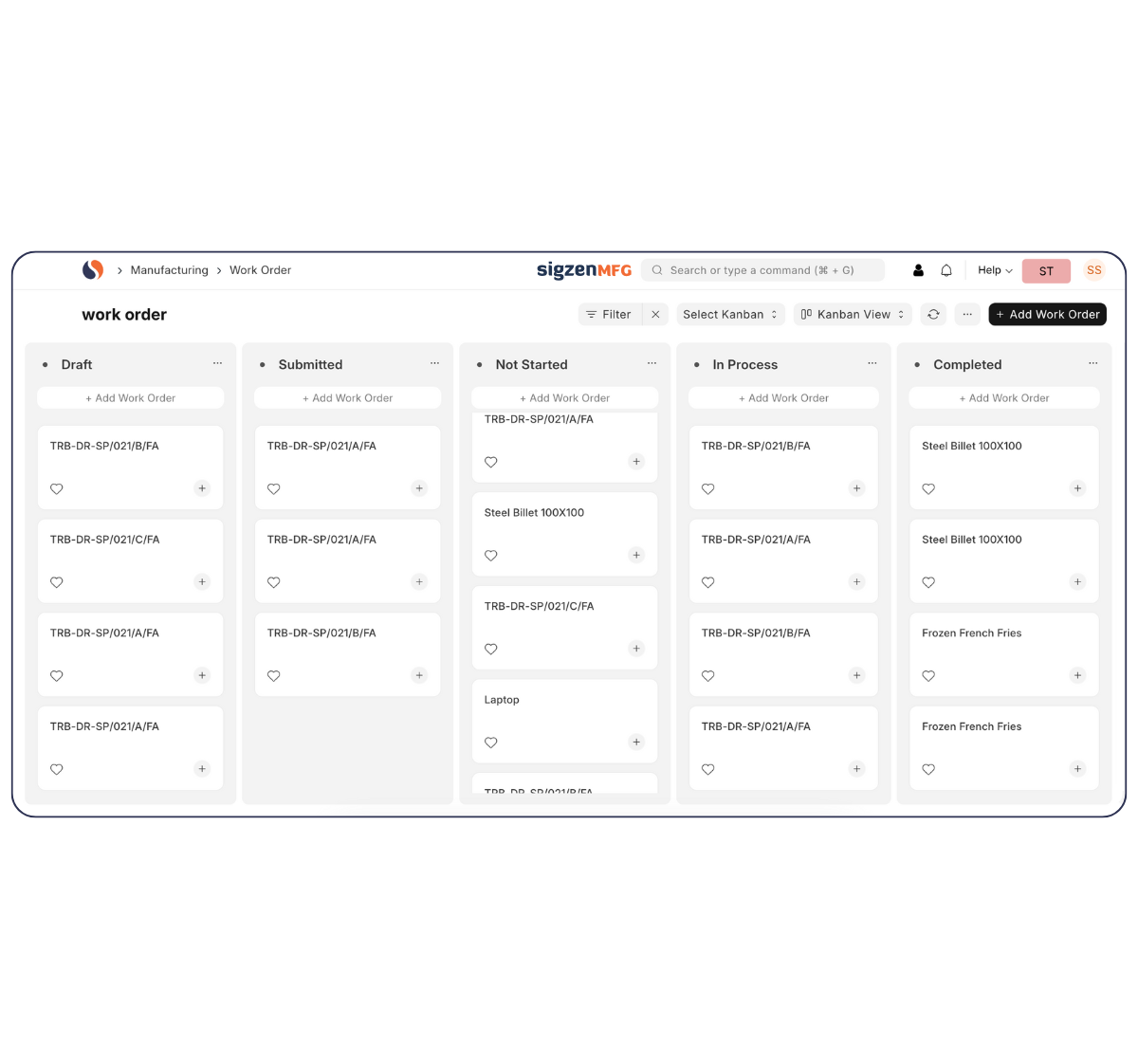

Employee-wise accountability

Assign work orders and job cards to specific employees, enforce mandatory QC or subcontracting steps before submission, and track performance at an operation level.

3. Integrated quality control and rework management

Configurable QC methods and forms

Use QC by serial number or by parameter, capture multiple readings per item, and manage scalable QC forms for 10+ items in a single run.

Automated QC generation from job cards

Automatically create QC records when a job card is completed or paused, ensuring no batch leaves production without inspection where required.

Structured rework workflows

Handle rejected quantities with defined rework paths at both QC and work order levels, minimizing scrap while keeping traceability intact.

4. Accurate costing and resource utilization

Costing of partial and final output

Maintain precise costing for partial output taken out during ongoing production, and compare BOM-based versus actual material consumption for variance analysis.

Asset and tool cost allocation

Allocate the cost of tools and assets to manufactured goods, linking assets and tools directly to workstations and operations for accurate resource costing.

Multiple UOM and warehouse planning

Track quantities in manufacturing and stock in multiple units of measure and plan raw material requirements from default item-wise warehouses.

5. Mobile-first visibility, reports, and dashboards

Real-time job and production tracking

Monitor job card status, accepted/rejected quantities, and resource utilization live from mobile, supported by job status dashboards (Not Started, Overdue, Pending, Completed).

Exception-focused reports

Use production analysis and work order material consumption reports to quickly identify delays, material variances, and bottlenecks on the shop floor.

Anytime, anywhere control

SigzenMFG syncs with your ERPNext database in real time so supervisors and management can review progress, approve operations, and take decisions directly from their phones.

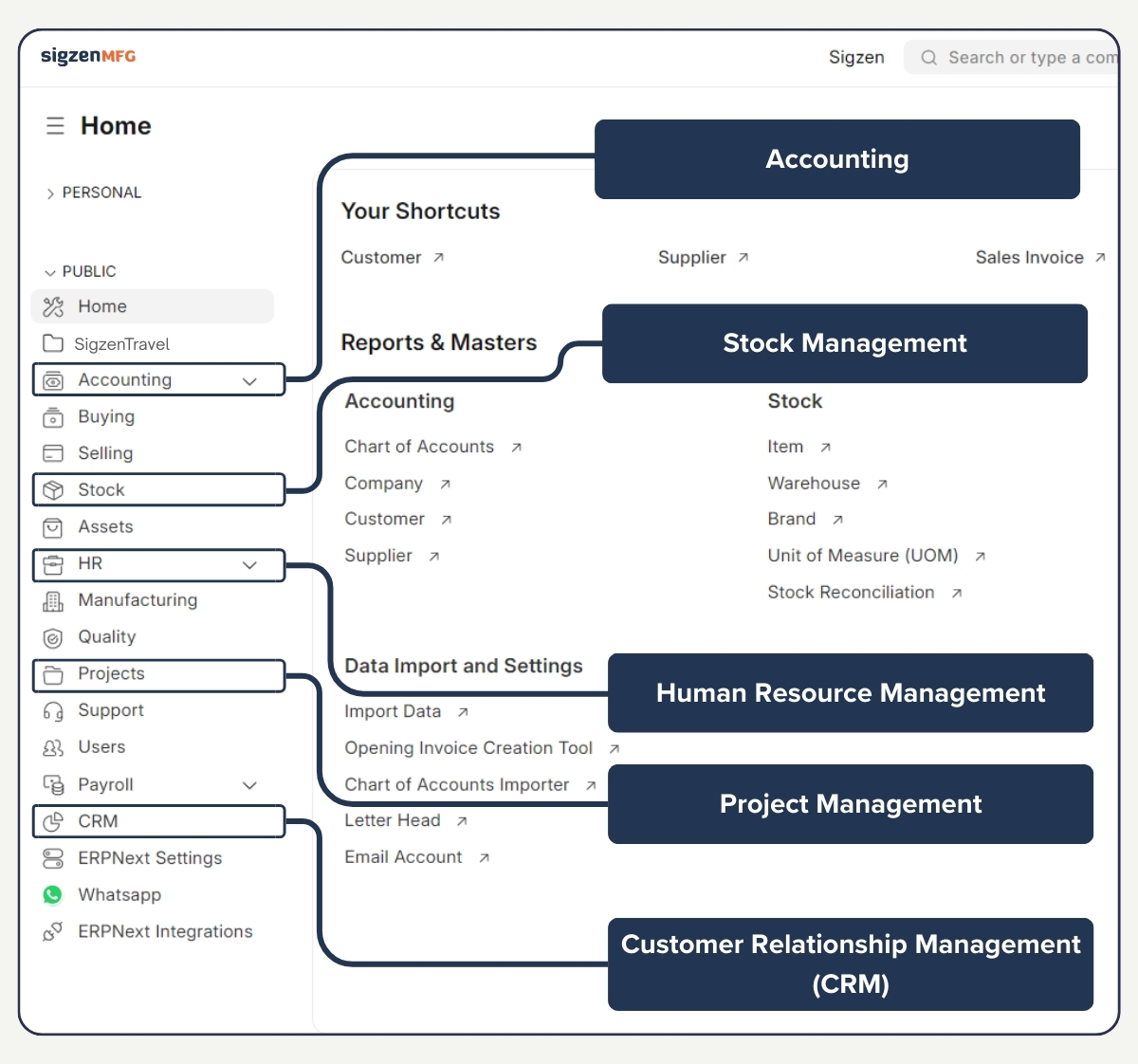

Integration with Other ERPNext Modules

SigzenMFG integrates seamlessly with core ERPNext modules like Inventory, Accounting, HR, Sales, CRM, Projects, and Service, ensuring all manufacturing, financial, and operational data stays in sync across one platform for real-time planning, costing, compliance, and decision-making

Case Studies

1. Electronics OEM with complex subcontracting

Challenge

A mid-sized electronics OEM relied on spreadsheets and manual follow-ups to manage subcontracting, leading to missing material, unclear job status, and delayed QC approvals. Partial assemblies and rework were not costed correctly, making it difficult to know true product margins.

Solution

SigzenMFG was implemented on their existing ERPNext instance with consolidated subcontracting orders, automated material transfers, and mobile job card tracking for in-house and outsourced operations. Automated QC records, parameter-based inspection, and structured rework flows were configured to ensure every lot passed through defined quality checks.

Results

The customer reduced subcontracting-related delays, gained real-time visibility of each job card, and cut manual coordination time on the shop floor. Accurate costing of partial outputs and rework improved margin clarity and supported better pricing and supplier negotiations.

2. Fabrication unit improving resource utilization

Challenge

A fabrication unit struggled to track which tools, fixtures, and workstations were used on which jobs, leading to idle assets, unplanned downtime, and unreliable costing. Supervisors lacked up-to-date production status, especially for night shifts, causing frequent rescheduling and missed delivery dates.

Solution

With SigzenMFG, assets and tools were linked to workstations and operations, and operators logged usage and downtime directly from mobile job cards. Job card status and production analysis dashboards gave management a live view of Not Started, In Progress, Overdue, and Completed work orders.

Results

The unit increased effective utilization of critical tools and reduced unplanned downtime, while better visibility allowed proactive rescheduling and on-time deliveries. Cost allocation to finished goods became more accurate, supporting data-driven investment decisions for new machines and tools.

Download SigzenMFG Mobile App

Experience real-time production control, job tracking, and quality visibility—right at your fingertips. Get started with SigzenMFG today.

Frequently Asked Questions

What is SigzenMFG and how does it benefit manufacturing operations?

SigzenMFG is a mobile-first manufacturing ERP based on ERPNext, designed to digitize production, automate subcontracting, streamline job cards, and improve shop floor control in real time. Manufacturers benefit by reducing manual errors, increasing production speed, and gaining complete traceability from raw materials to finished goods.

How does SigzenMFG support quality control and compliance?

SigzenMFG integrates automatic QC record generation, serial and parameter-based inspection, and enforces all mandatory checks before job closure. This ensures traceable quality data, compliance with customer and regulatory requirements, and enables structured rework workflows for rejected items.

Can SigzenMFG handle partial production and subcontracted operations?

Yes, SigzenMFG tracks partial output, scrap, and triggers progression of job cards only after partial products pass QC. Consolidated subcontracting orders, auto material transfers, and BOM-level configuration make outsourced and partially completed production entirely visible and manageable.

Which other ERPNext modules does SigzenMFG integrate with?

SigzenMFG synchronizes live data with ERPNext modules including Inventory (stock and warehouse), Accounting & Finance (costing, WIP, profitability), HR & Payroll (employee tracking), Sales & CRM (production vs delivery alignment), and Projects (engineer-to-order production tracking).

Is SigzenMFG suitable for SMEs and scalable for enterprises?

SigzenMFG’s mobile-centric workflows, built-in automation, and flexible BOM/job card structure enable small and medium-sized factories to adopt digital shop floor management with minimal IT overhead. It also scales for large plants with complex multi-step, multi-location operations.

What kind of production and costing analytics does SigzenMFG provide?

Users get real-time dashboards for job card status, production progression (monthly/weekly), consumption variance vs BOM, accepted/rejected quantities, and allocation of asset/tool costs for precise margin calculation by product, work order, or production batch.

How can SigzenMFG be implemented in my existing ERPNext environment?

SigzenMFG is deployed as an extension to your current ERPNext instance, with full configuration support from Sigzen Technologies. The system can be tailored to your BOMs, shop floor layout, and costing model, and integrates existing item, asset, and employee records.

Does Sigzen Technologies offer post-implementation support?

Yes, Sigzen provides comprehensive post-go-live support for SigzenMFG, including process optimization, troubleshooting, and training, to ensure ongoing value and user adoption in your plant.

Is SigzenMFG available for mobile devices and remote teams?

SigzenMFG supports iOS and Android, letting operators and supervisors log production, QC, and resource data from anywhere, on any shift, supporting remote approvals and real-time decision-making.

How does SigzenMFG improve manufacturing ROI?

By automating manual tasks, minimizing rework and scrap, improving visibility into costs and throughput, and enabling accurate production forecasting, SigzenMFG helps manufacturers cut operating costs, deliver on time, and maximize profitability.

Start your smart manufacturing journey with SigzenMFG

Experience how a mobile-first, ERPNext-based solution can streamline your production, improve costing accuracy, and give real-time shop-floor visibility. Book a free consultation to see SigzenMFG in action and learn how it can be tailored to your manufacturing processes and growth plans.