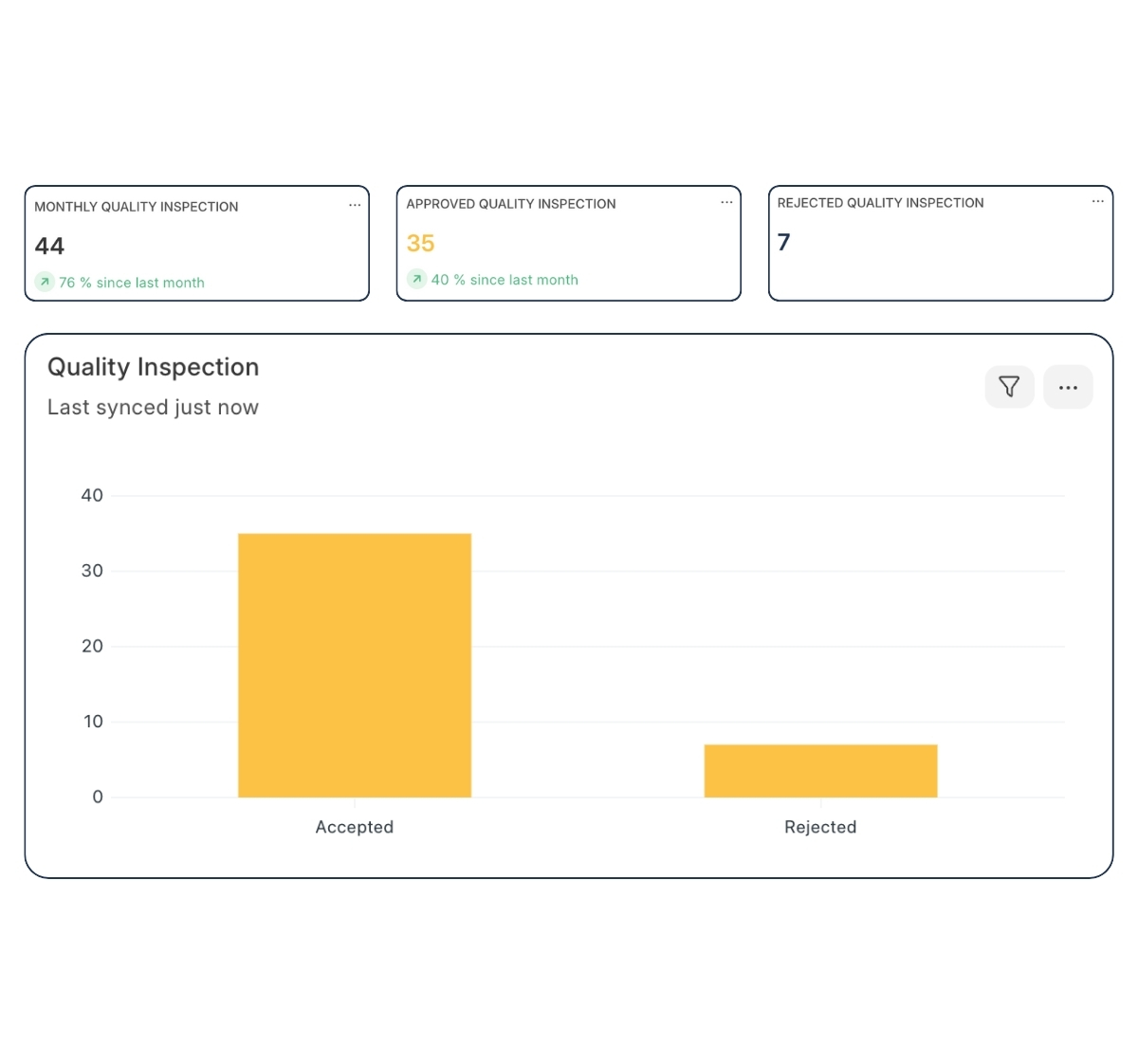

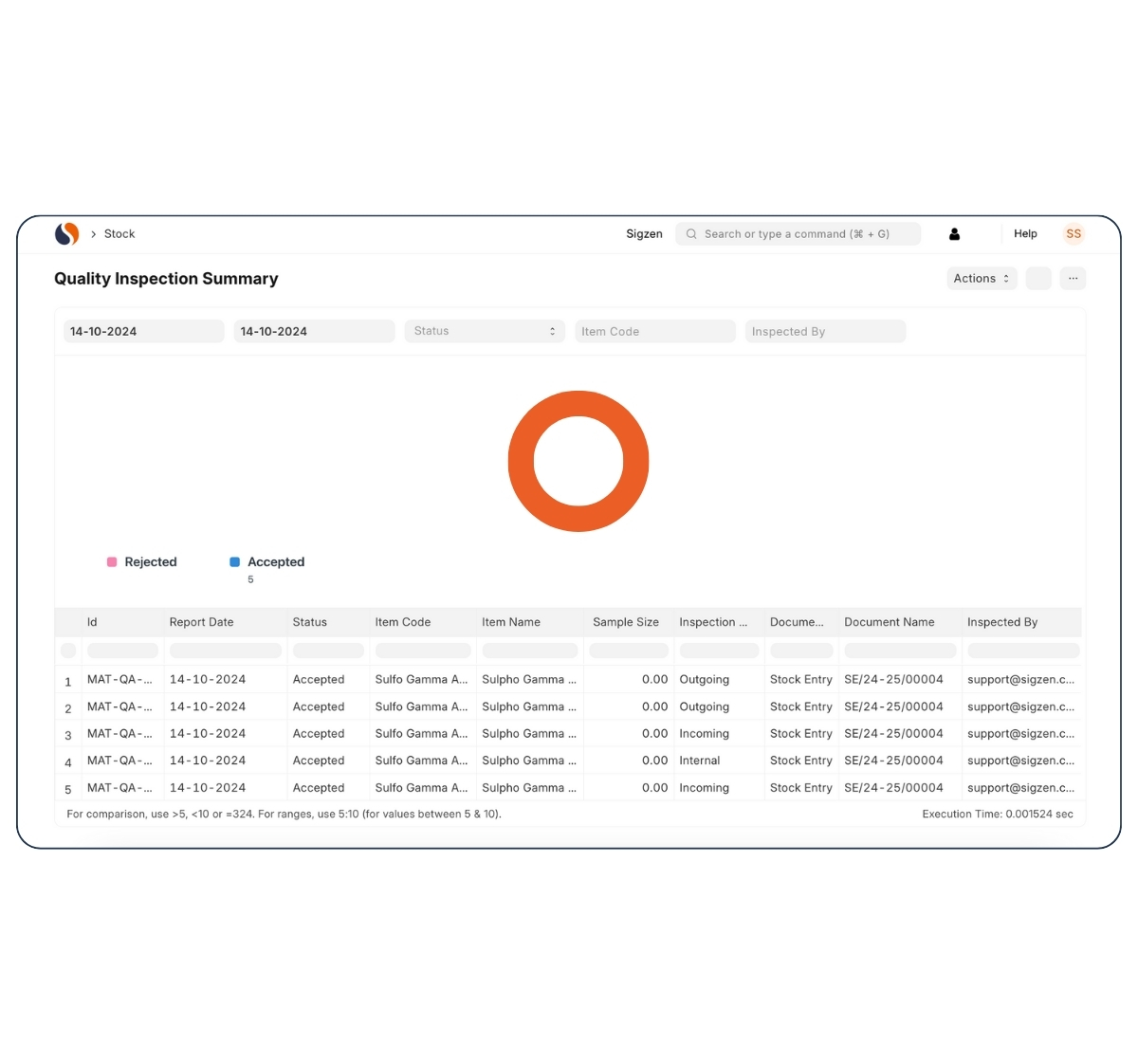

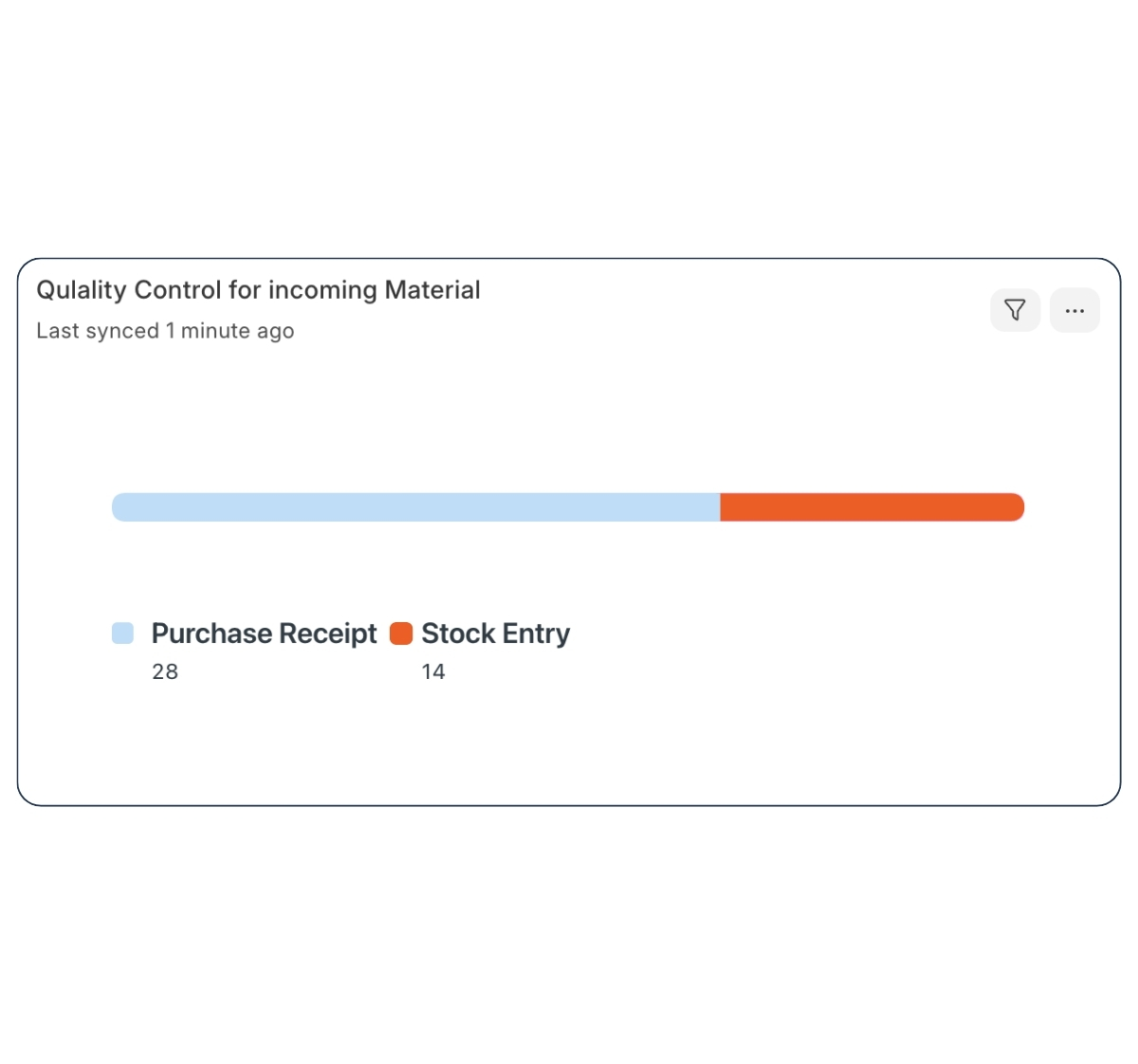

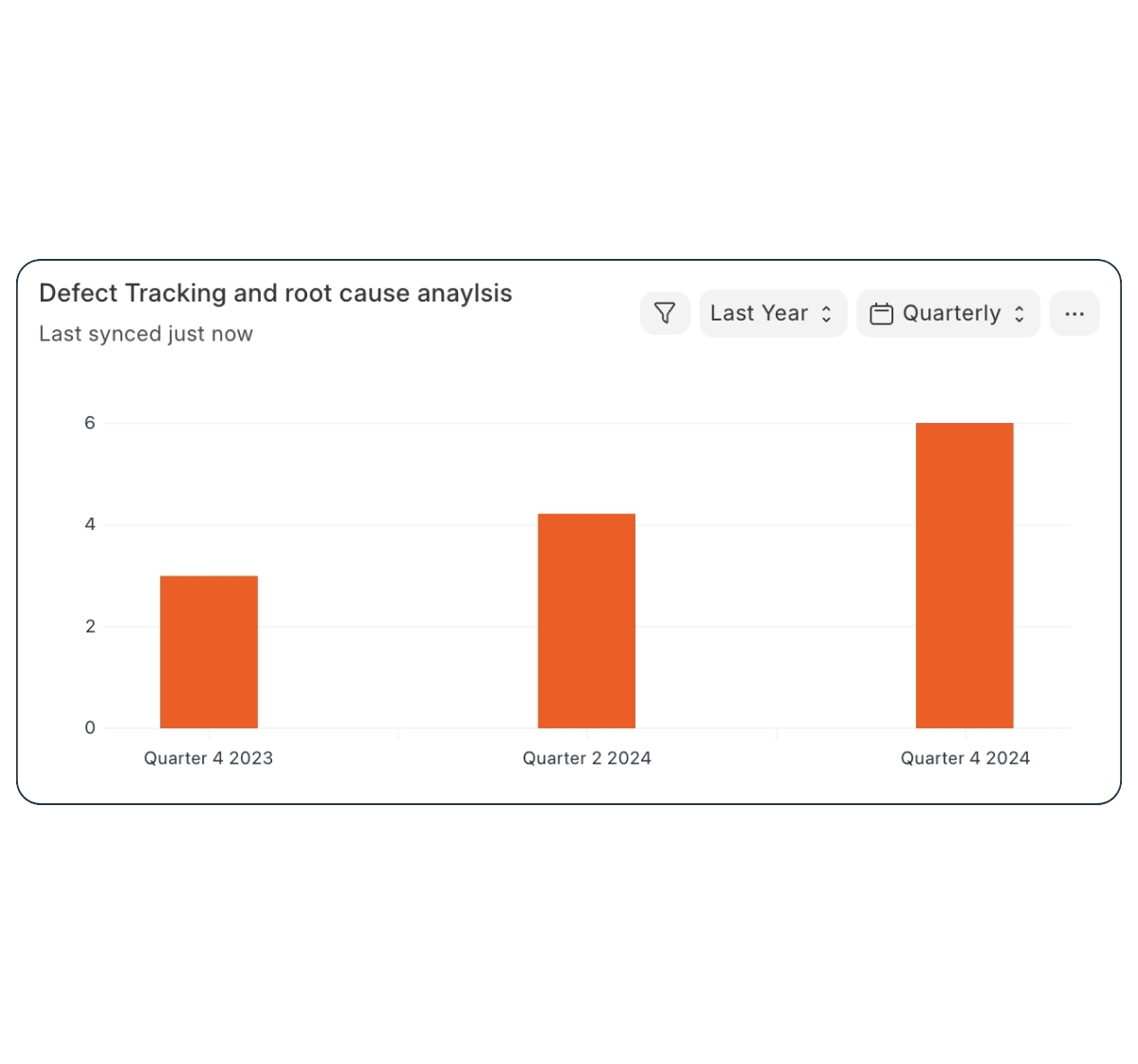

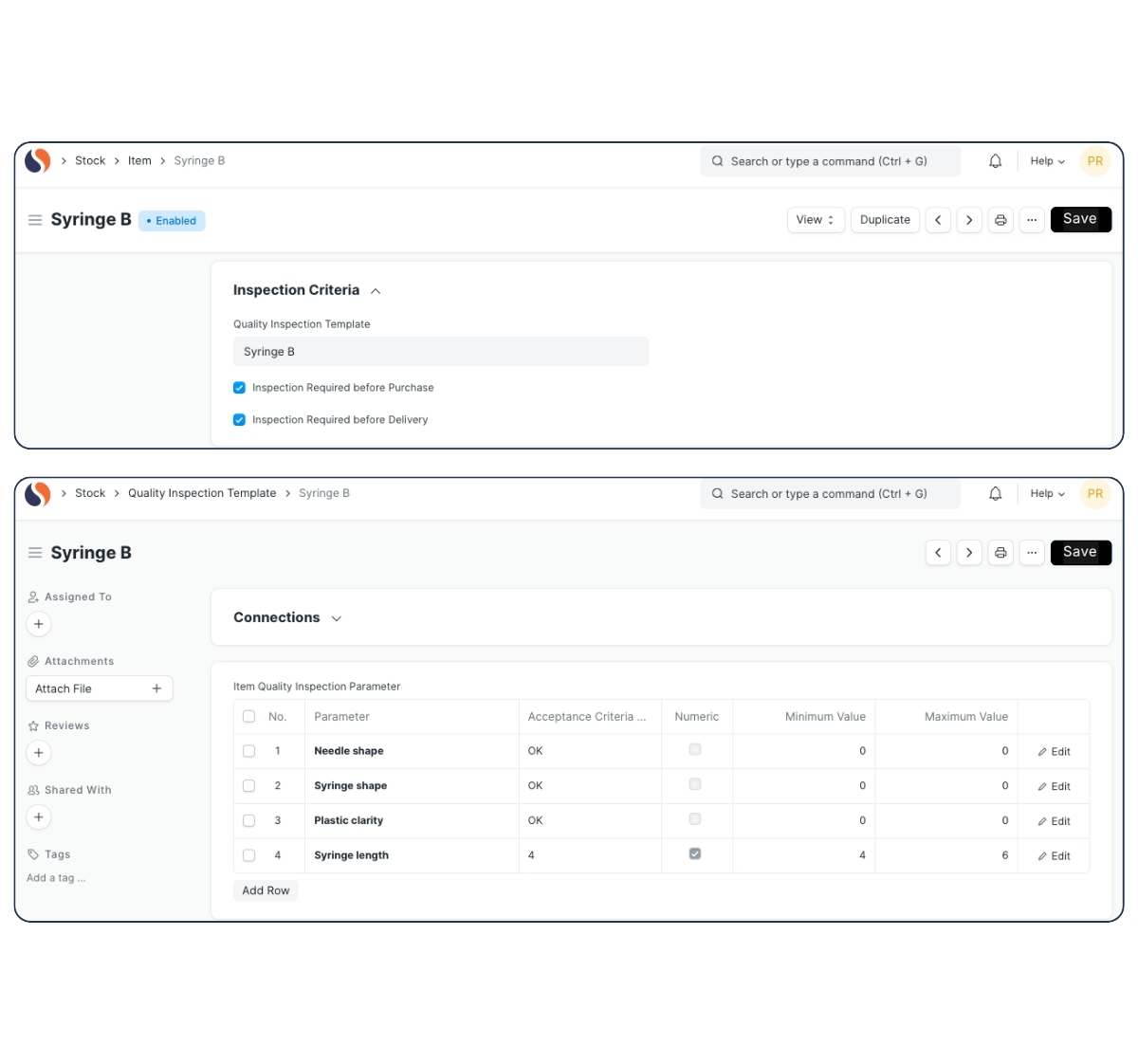

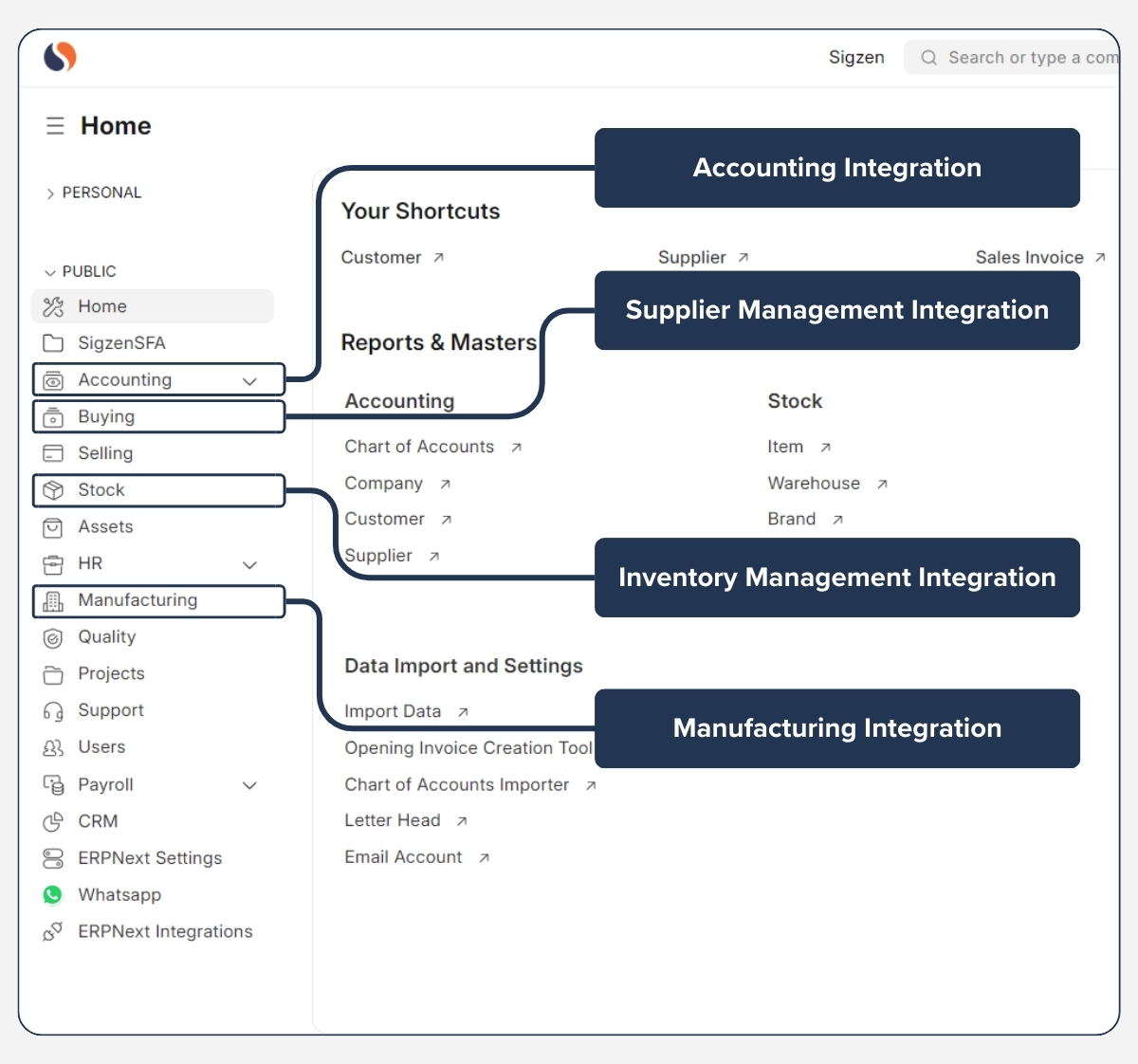

The Quality Control Module in ERPNext provides businesses with a comprehensive tool to ensure that products meet defined quality standards at every stage of the production and delivery process. This module allows businesses to establish rigorous quality inspection protocols, track product quality metrics, and integrate quality management seamlessly into manufacturing, inventory, and procurement workflows, creating a robust QMS.

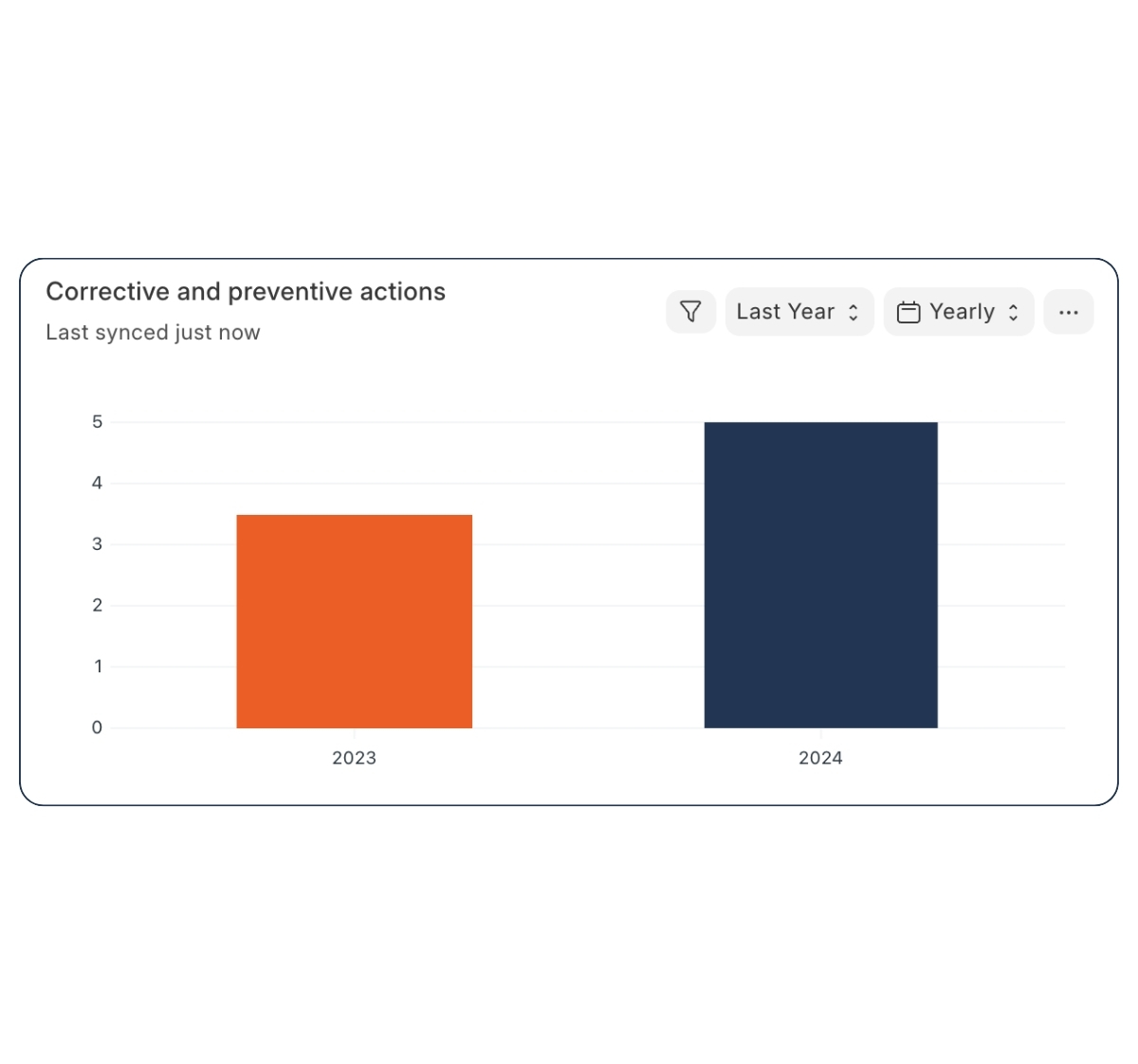

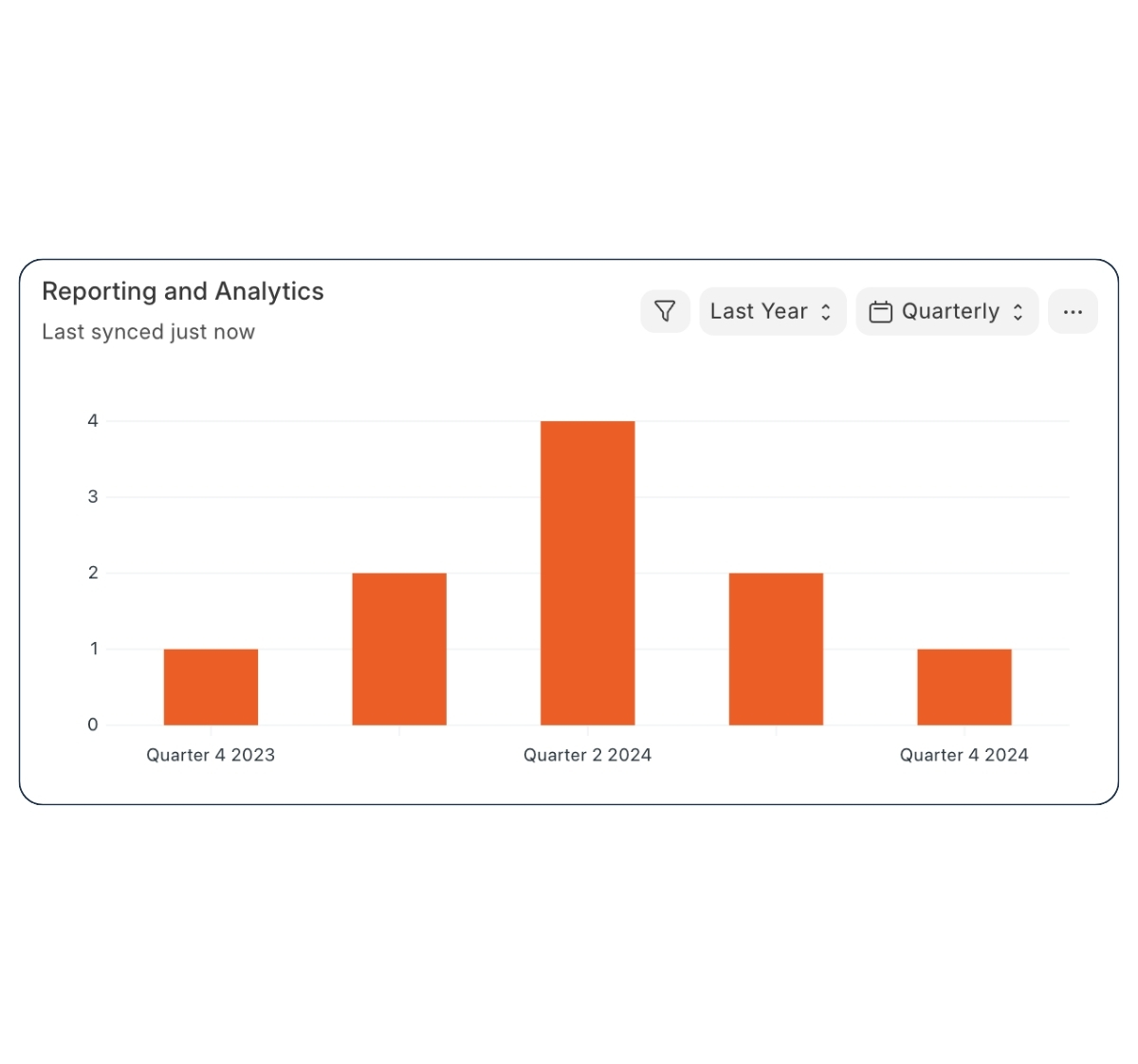

Quality control is crucial for maintaining customer satisfaction, reducing returns and rework, and ensuring compliance with industry regulations. With ERPNext’s Quality Control Module, businesses can set up custom quality checkpoints, automate inspection schedules, manage non-conformances, and generate detailed reports to ensure consistent product quality and drive continuous improvement.