SigzenMETAL is a specialized metal industry ERP solution developed by Sigzen Technologies, built on the robust ERPNext platform, specifically designed to meet the complex needs of the metal industry. SigzenMETAL offers advanced features to streamline manufacturing processes, optimize resource allocation, and enhance quality control, all while simplifying complex metal subcontracting workflows. By integrating critical manufacturing functions, like MES capabilities and improving real-time visibility across operations, SigzenMETAL helps metal manufacturers boost efficiency, reduce costs, and maintain high-quality standards within a single, unified cloud ERP platform whether you’re managing custom metal products or large-scale industrial manufacturing.

SigzenMETAL

Tailored ERPNext Software solutions for the Metal industry

Key Features

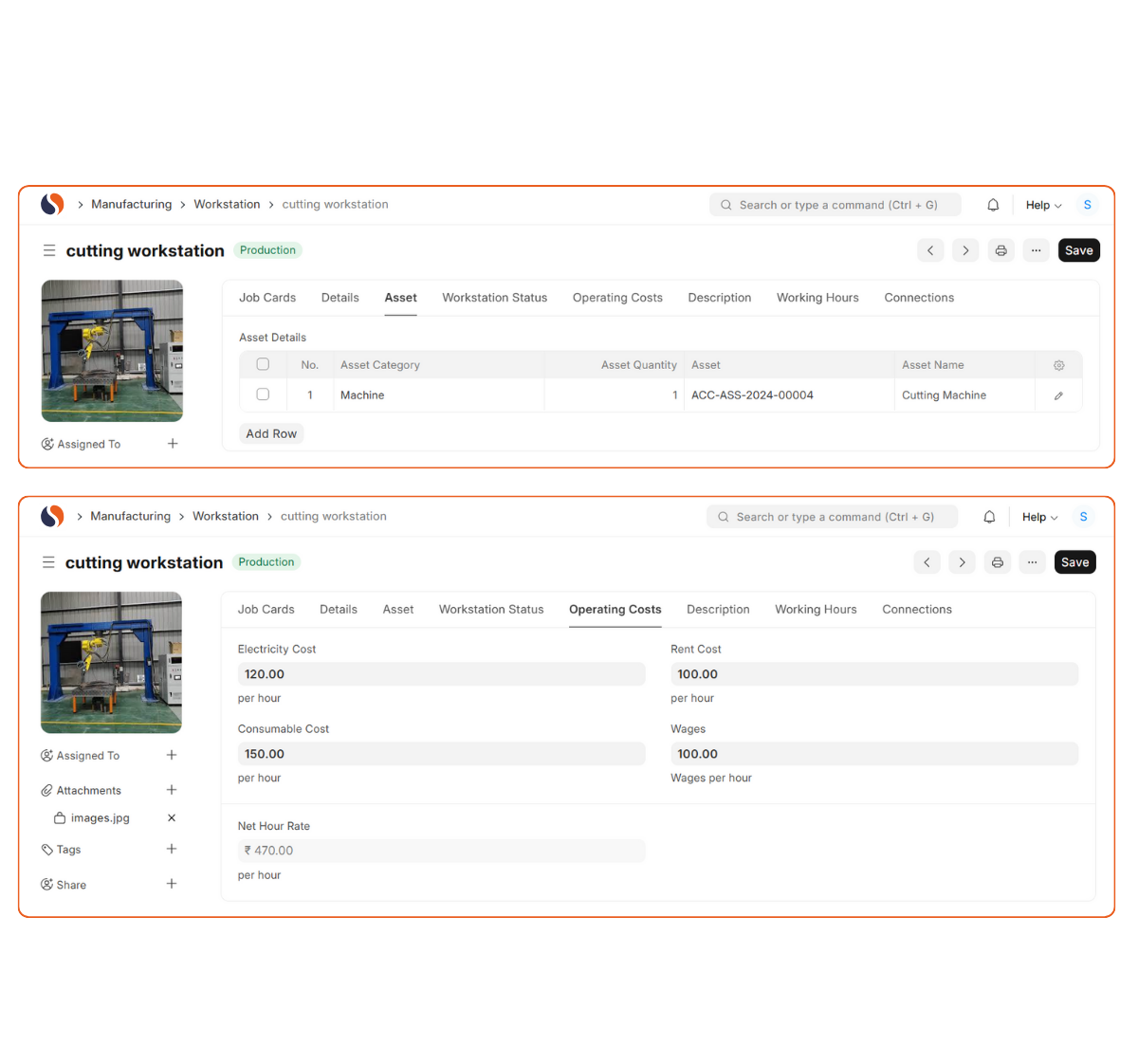

1. Asset and Workstation Integration for Manufacturing

Streamlined Operations

Link assets and tools directly with workstations to enhance metal manufacturing efficiency.

Precise Resource Allocation

Assign tools and assets to specific operations in the manufacturing cycle for optimized resource utilization and tracking.

Accurate Cost allocation of tools

Accurately allocate tool and assets cost to the manufactured goods for better manufacturing cost management.

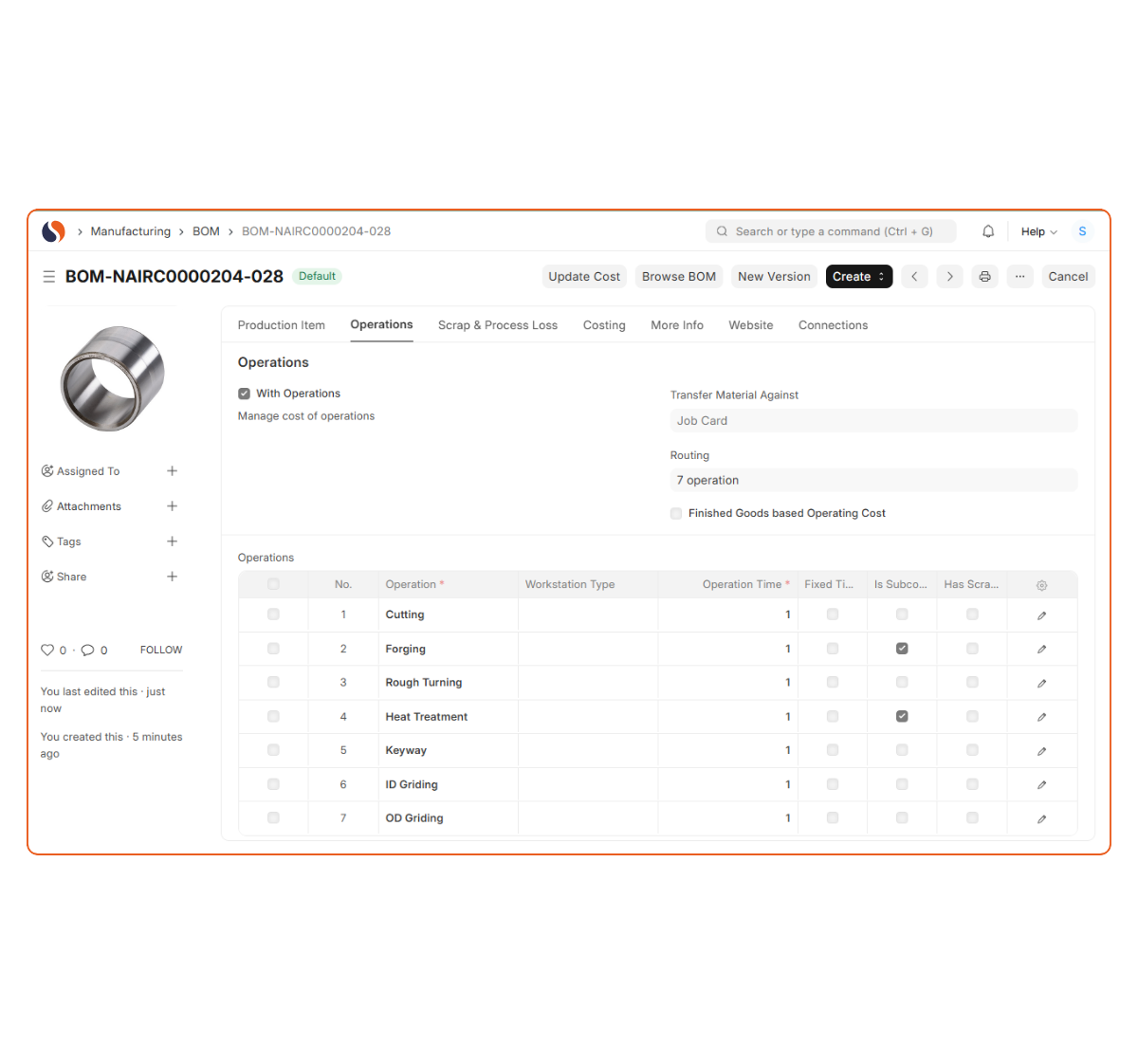

2. Advanced Metal Subcontracting Workflow

Configurable Subcontracting at BOM Level

Customize subcontracting workflows by selecting operations for subcontracting directly within the Bill of Materials (BOM) in your metal ERP.

Seamless Material Transfers

Effortlessly transfer raw materials to job worker warehouses during subcontracting order creation via the ERP system.

Consolidated Orders

Create a single subcontracting order for multiple job cards, reducing administrative overhead and improving traceability.

Automation

Automatically complete job cards when subcontracted metal items are received and auto stock entries creation is triggered.

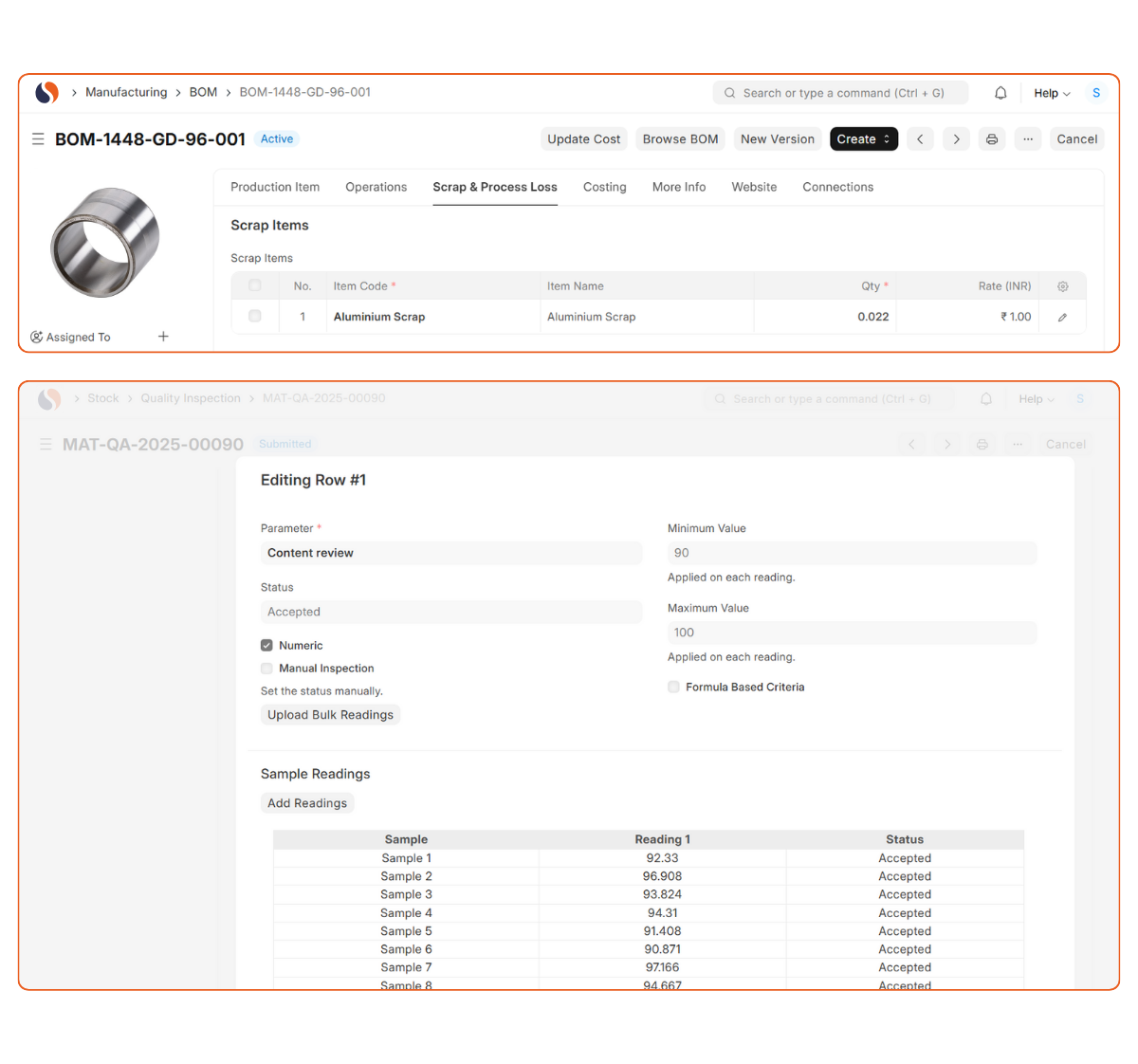

3. Comprehensive Quality Control (QC) and Testing for Metals

Automated QC Creation

Generate QC records automatically upon job card completion or pausing within the metal ERP.

Scrap and Partial Completion Tracking

Record scrap and completed quantities in real-time for paused job cards for accurate yield calculation.

Dynamic Job Progression

Enable the next job card to start when partial quantities are produced and QC tested.

Scalable QC Forms

Create QC forms for more than 10 metal items and manage multiple readings for a single item with ease.

Bulk Autofill

Save time by auto-filling item readings based on test results using predefined parameters.

Rework Workflow

Handle rework seamlessly for rejected quantities at both QC and work order levels with integrated rework workflows.

Scrap Management

Manage scrap ensuring processes align with industry benchmarks and re-use of metal scrape with extra added process cost, this will allow tracking accurate costing of manufacturing including scrap processing cost and material recovery.

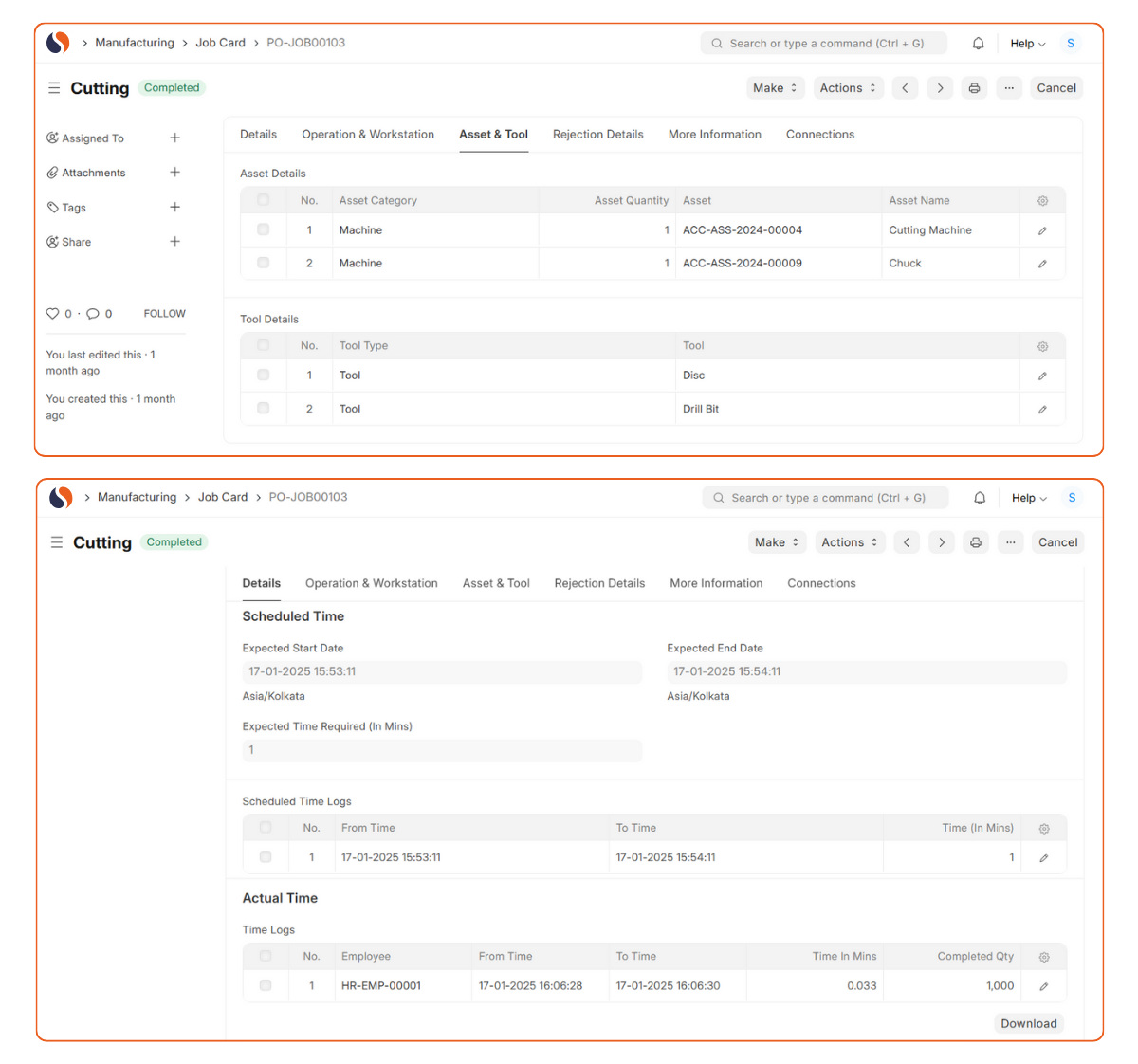

4. Enhanced Metal Manufacturing Job Card Functionality

Asset and Tool Availability Checks

Prevent job card initiation if essential tools and assets are unavailable through real-time checks.

Timelog Management

Maintain detailed time logs for tool and asset usage for accurate costing.

Tool & Asset Flexibility

Mark tool transfers, asset repairs, maintenance, and movement directly within the Job Card interface in the ERP.

Inspection Compliance

Restrict job card submission if quality inspections or subcontracting cycles are incomplete, ensuring metal production workflow integrity.

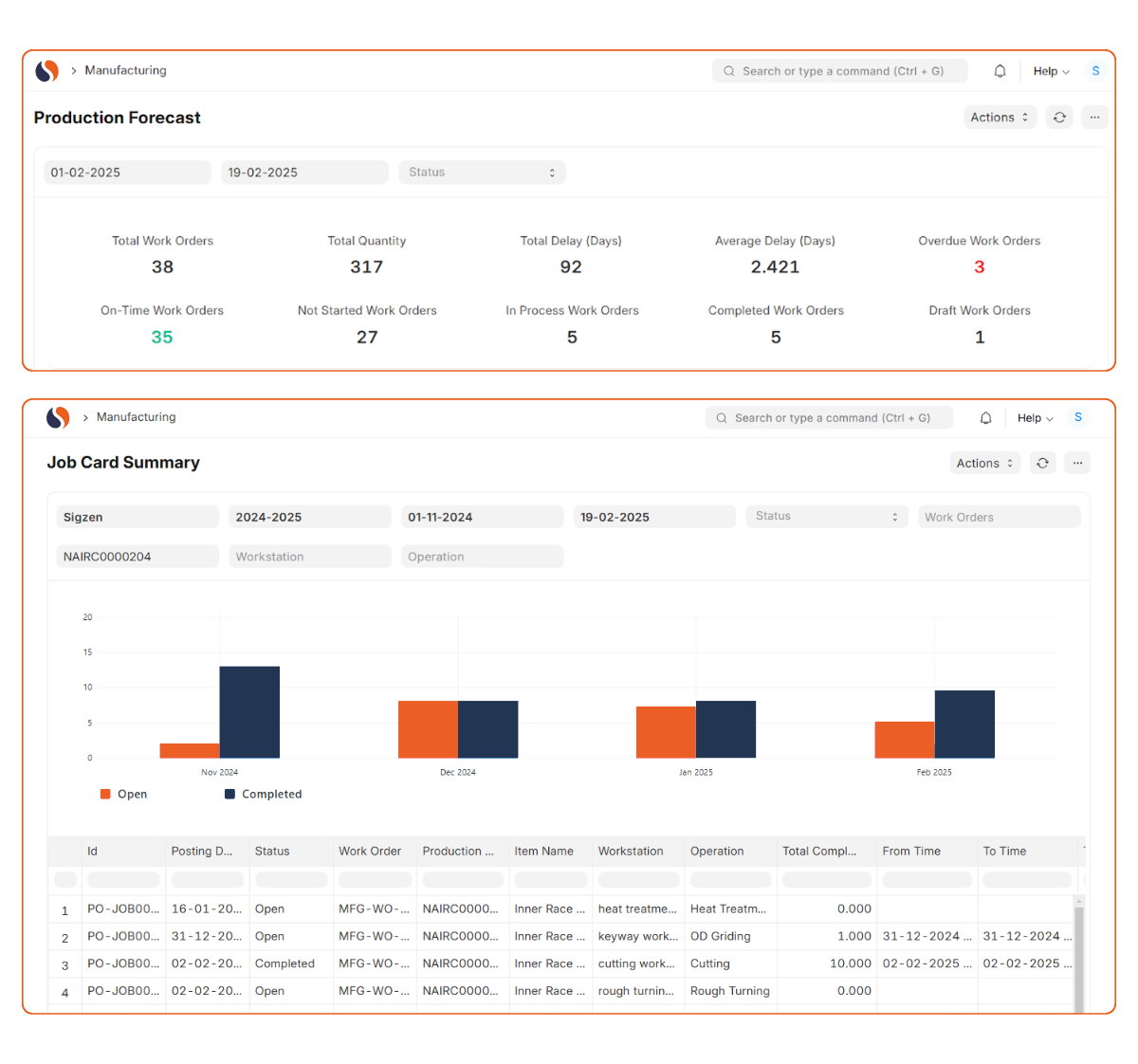

5. Metal Manufacturing Reports and dashboards

Job Card Status and Progress Report

Offers a comprehensive view of each job card’s status and progress,accepted and rejected quantity, asset and tool usage essential for daily metal shop floor operations management.

Production Forecast Report

Tracks upcoming manufacturing schedules with expected completion dates based on open Work Orders and Sales Orders. Useful for metal production planning and forecasting.

Employee Production Efficiency

Evaluates individual employee efficiency by comparing actual output vs. expected output. Helps in performance analysis and workforce optimization on the shop floor.

Scrap Variance

Compares actual scrap generated during metal manufacturing against the expected scrap as per BOM. Helps in identifying excessive material wastage and improving yield.

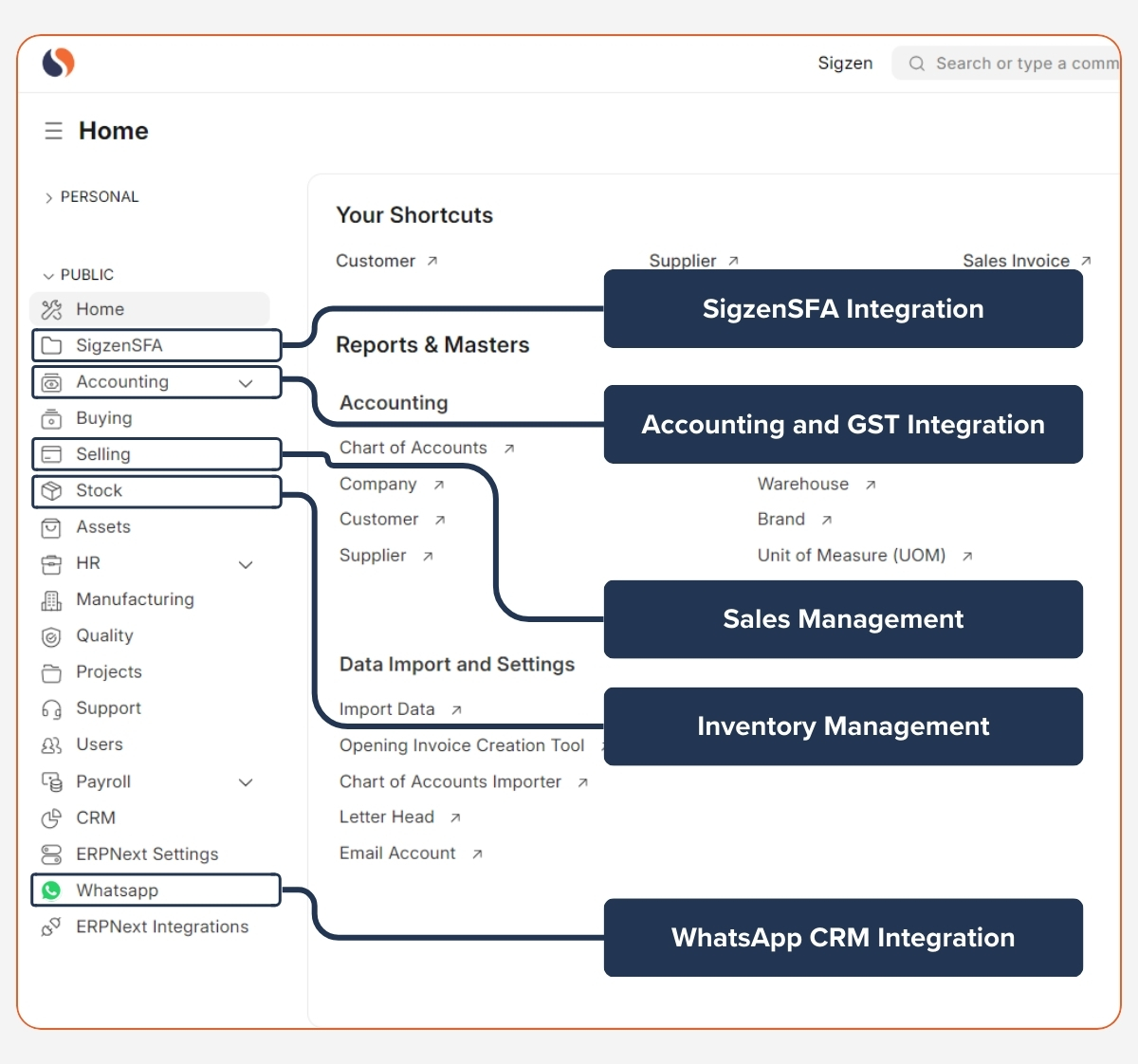

Integration With Other ERPNext Modules

Case Studies

1. Streamlining Complex Fabrication & Subcontracting for a Large Industrial Manufacturer

Challenge

A large manufacturer specializing in custom industrial metal components faced significant hurdles managing complex, multi-level Bills of Materials (BOMs) and coordinating numerous subcontracting operations across an extensive vendor network. Lack of real-time visibility into job card progress and inefficient material transfers to subcontractors led to frequent production delays, increased administrative costs, and difficulty in meeting tight deadlines.

Solution

The implementation of SigzenMETAL provided robust tools to manage their intricate processes. The Advanced Metal Subcontracting workflow allowed configuration directly at the BOM level, automated the transfer of raw materials to job worker warehouses, and enabled the consolidation of multiple job cards into single subcontracting orders. Enhanced Job Card Functionality offered real-time status updates and integrated asset/tool tracking for improved shop floor control within the metal ERP system.

Results

The manufacturer achieved a 25% reduction in average subcontracting lead times, a 15% decrease in administrative overhead related to managing subcontracting orders, and improved their overall on-time delivery rate by 20% due to the enhanced visibility and streamlined process automation provided by SigzenMETAL.

2. Enhancing Quality Control and Reducing Scrap in Precision Metal Parts Manufacturing

Challenge

A medium-sized company producing high-tolerance precision metal parts for the aerospace sector struggled with inconsistent quality control procedures across different shifts, leading to high scrap rates. Inefficient rework processes and difficulty in accurately tracking material wastage impacted profitability and cost estimation accuracy.

Solution

SigzenMETAL’s Comprehensive Quality Control (QC) and Testing module was implemented, enabling automated QC record generation upon job card completion or pause. Standardized rework workflows for rejected quantities were established directly within the metal ERP. The Scrap Variance reporting feature provided detailed insights into actual vs. expected scrap, helping identify key areas for process improvement.

Results

The company successfully reduced its overall scrap rate by 30% within the first year. First-pass yield (parts passing QC first time) improved by 18%. Furthermore, accurate tracking of scrap, including re-use value, allowed for more precise manufacturing cost calculations and optimized material procurement, leading to improved profit margins.

Frequently Asked Questions

How can SigzenMETAL benefit metal industry businesses?

SigzenMETAL enhances operational efficiency by automating key metal manufacturing processes like inventory tracking, production planning, and sales management within a unified ERP system. It reduces manual errors, improves resource utilization, and provides real-time insights to help businesses make data-driven decisions and increase profitability.

How does SigzenMETAL improve inventory management?

SigzenMETAL offers real-time tracking of raw materials, work-in-progress (WIP), and finished metal goods, optimizing stock levels and reducing waste. Its advanced inventory management features ensure accurate order fulfilment, better stock rotation, and efficient resource utilization.

Can SigzenMETAL handle complex production processes?

Yes, SigzenMETAL is equipped to manage intricate production workflows, including batch processing, job scheduling, shop floor control, and machine maintenance. It ensures seamless coordination between departments, leading to improved production efficiency and reduced lead times.

Is SigzenMETAL customizable to specific business needs?

Absolutely. SigzenMETAL is built on the flexible ERPNext/Frappe platform that allows customization to align with unique business requirements, ensuring the solution adapts to your specific operational processes in the metal industry.

What kind of support and training does Sigzen provide for SigzenMETAL users?

Sigzen offers comprehensive support, including initial ERP implementation assistance, user training sessions, and ongoing technical support to ensure your team can effectively utilize SigzenMETAL to its fullest potential for your metal business.

Begin Your Metal ERP Journey with a Free Consultation

Optimize your metal operations with SigzenMETAL. Contact us today for a demo and discover how our metal industry ERP solution can streamline logistics, automate sales processes, and boost overall efficiency.