SigzenCHEM is a tailored Chemical ERP solution built on the robust ERPNext platform designed to address the specific challenges of the chemical manufacturing industry in India and globally. It supports operations like batch production, formulation management, and regulatory compliance. SigzenCHEM offers tools for in-house manufacturing, subcontracting, sample production, and rigorous quality control. By optimizing production processes and ensuring product safety, this cloud-based ERP solution helps chemical manufacturers streamline operations, reduce costs, and maintain formula confidentiality, all within a single, integrated platform—whether producing specialty chemicals or large-scale industrial products.

SigzenCHEM

Tailored ERPNext Software Solution for the Chemical Industry

Key Features

1. Streamlined Manufacturing

Chemical manufacturing requires seamless coordination of equipment, materials, and labor. SigzenCHEM’s Streamlined Manufacturing feature ensures optimal batch production while reducing waste and downtime, helping you maintain high-quality output using our chemical ERP.

Optimize Batches

Improve production efficiency by optimizing batch sizes and reducing waste, ensuring that raw materials are utilized effectively with process manufacturing tools.

Enhance Quality

Maintain product quality by closely monitoring production parameters and ensuring consistent results batch after batch.

Peak Equipment Utilization

Keep equipment running at peak performance to reduce repair costs and downtime, ensuring that your production lines operate efficiently with integrated maintenance schedules.

Minimize Downtime

Use advanced scheduling tools to minimize equipment downtime and avoid production bottlenecks in your chemical plant.

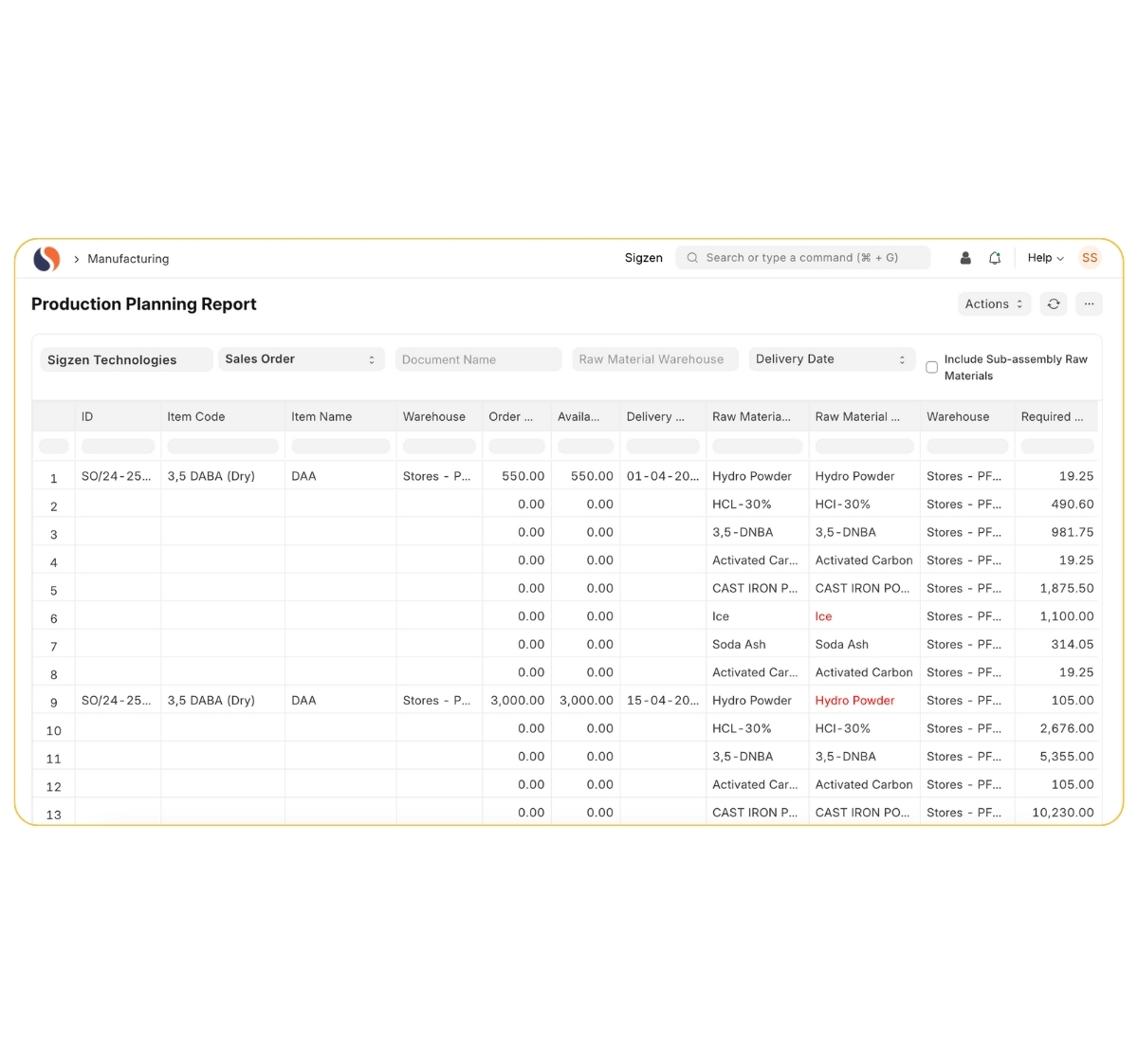

Advanced MRP

Plan material requirements based on demand forecasts using Advanced MRP, ensuring that you always have the right materials available for production.

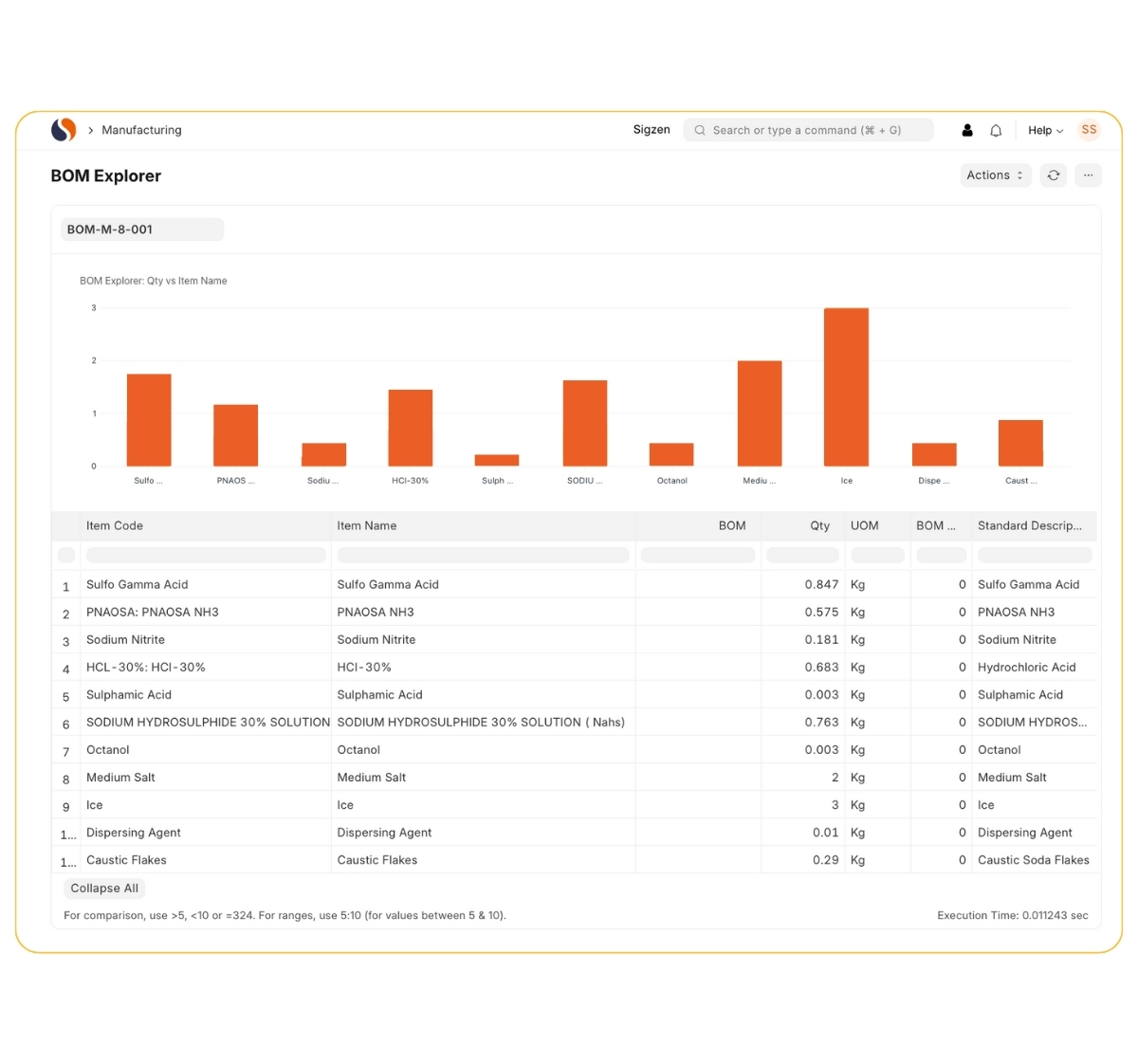

2. Formulation Management

The chemical industry relies heavily on accurate formulations to ensure product quality and regulatory compliance. SigzenCHEM provides advanced tools for Formulation Management to help you manage proprietary formulas with confidence within the ERP.

Formula Adjustments

Easily adjust formulas to improve product quality or increase production efficiency, helping you adapt quickly to market demands or regulatory changes while maintaining version control.

Research and Development (R&D)

Support R&D initiatives by tracking formula changes, test batches, and quality outcomes in a dedicated module. This helps you bring new products to market faster while ensuring consistency in quality.

Confidentiality of Formulations

Protect proprietary formulas with role-based access controls and encryption, ensuring that only authorized personnel can view or modify sensitive chemical formulation information.

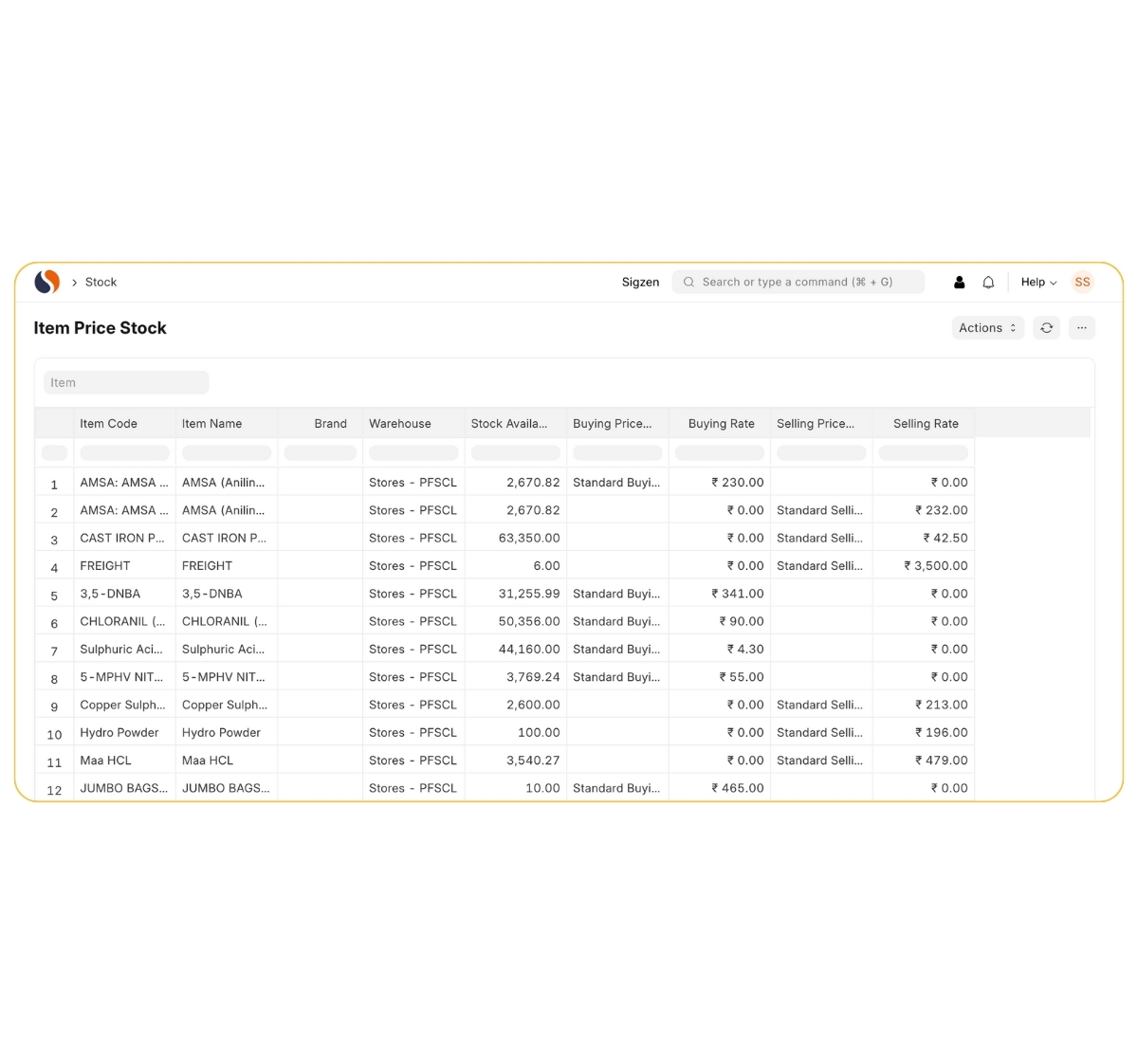

3. Chemical Inventory and Costing Management

Effective inventory management is essential for chemical manufacturers to avoid shortages, overstocking, or waste. SigzenCHEM offers Batch/Lot Wise Inventory Management to ensure that every material is tracked accurately throughout the supply chain and production process.

Batch/Lot Wise Management

Track materials and finished products by batch or lot, ensuring full traceability and compliance with industry standards like GHS.

Auto Reordering

Automatically reorder materials based on minimum inventory levels using the ERP system, ensuring that you never run out of critical raw materials or products.

Cost Accounting

Calculate the accurate cost of production by considering by-products, waste, and recycling efforts, giving you a clear picture of your true chemical production costs.

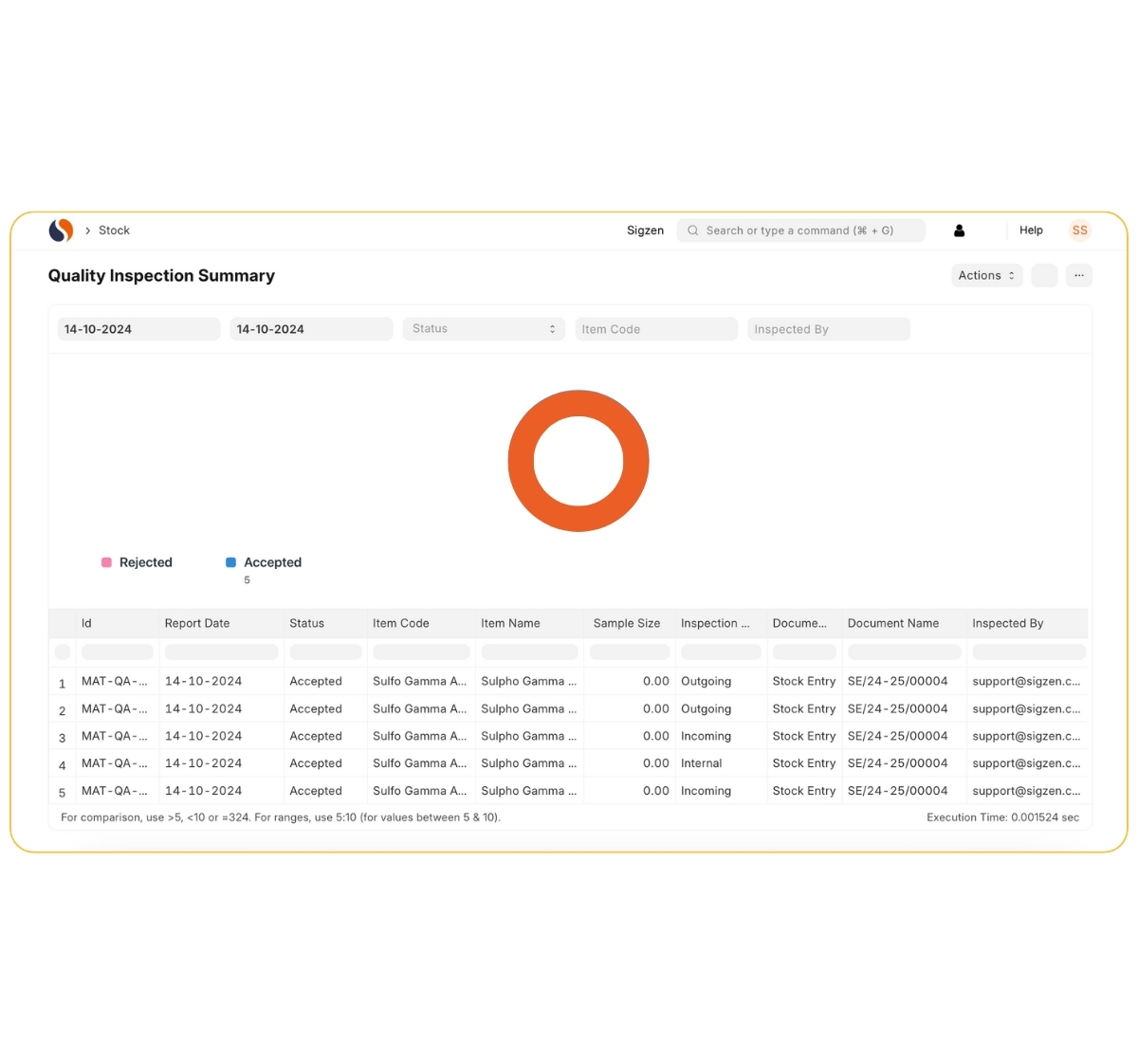

4. Chemical Quality Control (QC)

Maintaining rigorous quality standards is vital in the chemical industry to ensure product safety and avoid costly recalls. SigzenCHEM’s Quality Control feature allows you to monitor and enforce strict quality protocols throughout the production process using the ERP’s QC module.

Rigorous Quality Controls

Implement automated quality checks at various stages of production to meet internal standards and customer expectations for chemical products.

Safety Standards Compliance

Ensure compliance with both local and international safety regulations (e.g., REACH, GHS), minimizing the risk of recalls or legal issues.

Minimize Recalls

By maintaining high product standards, you can minimize product recalls and safeguard your reputation in the competitive chemical market.

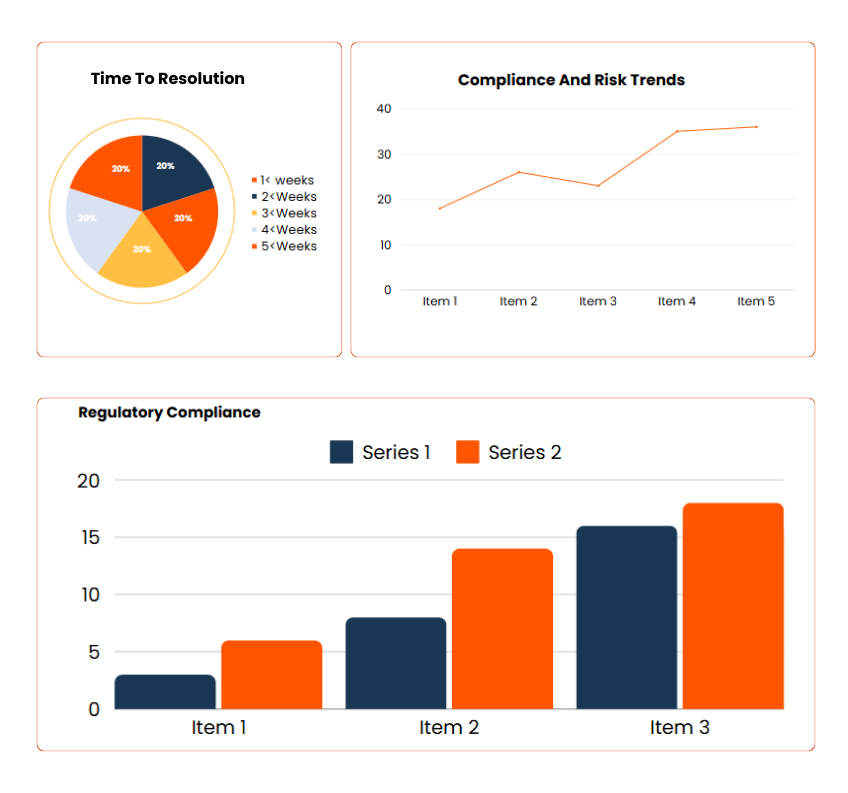

5. Regulatory Confidence & Compliance

Chemical manufacturers must adhere to a wide array of regulatory requirements to operate legally and safely. SigzenCHEM’s Regulatory Confidence feature allows businesses to stay ahead of regulations and generate the necessary compliance reports easily from the ERP.

Compliance Reporting

Automatically generate compliance reports for regulatory authorities, ensuring that your business stays in good standing with safety and environmental regulations in India and abroad, aligning with guidance from industry bodies like the Indian Chemical Council (ICC).

Stay Ahead of Regulations

Keep up with changing regulations by leveraging real-time updates and automated workflows that adapt to new compliance requirements within the chemical ERP system.

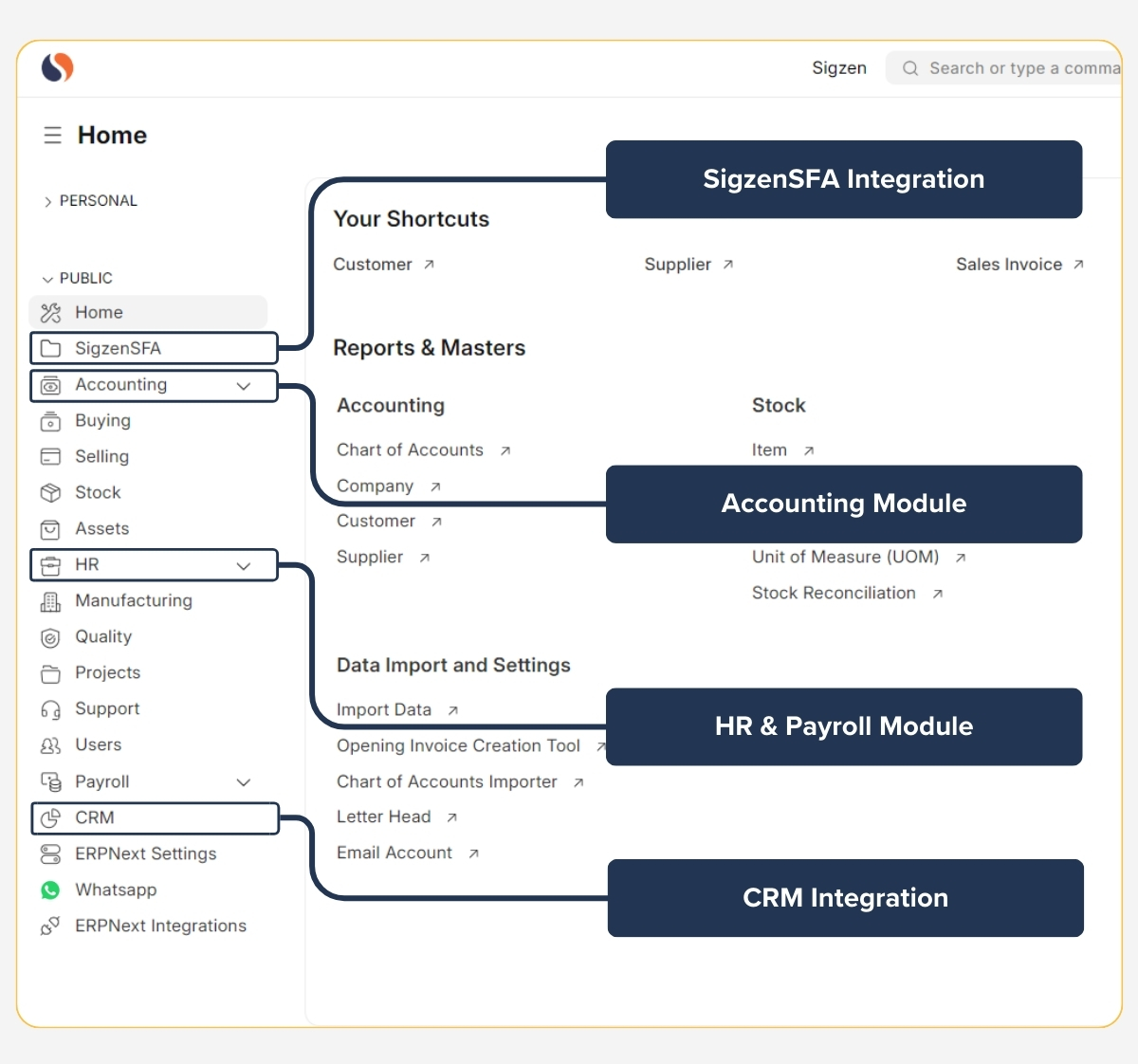

Integration with Other ERPNext Modules

SigzenCHEM integrates seamlessly with other ERPNext modules and third-party applications, offering a holistic solution for chemical manufacturers. This enables businesses to manage all aspects of their operations from one platform.

Case Studies

1. Enhancing Batch Production Efficiency for a Specialty Chemical Manufacturer

Challenge

A specialty chemical manufacturer based in Gujarat struggled with batch inconsistencies and wastage, leading to higher production costs.

Solution

By implementing SigzenCHEM’s streamlined manufacturing and advanced MRP features within their ERPNext system, the company optimized batch sizes and reduced wastage, improving overall efficiency.

Results

The manufacturer saw a 20% reduction in raw material wastage and a 15% improvement in production efficiency, allowing them to meet customer demands more effectively and improve margins.

2. Ensuring Regulatory Compliance for a Chemical Formulation Plant

Challenge

A chemical formulation plant faced challenges in staying compliant with constantly changing industry regulations, leading to potential fines and operational risks during audits.

Solution

SigzenCHEM’s regulatory confidence tools automated the generation of compliance reports (like MSDS/SDS precursors), helping the business stay up-to-date with safety regulations.

Results

The business was able to reduce compliance reporting time by 30% and minimize the risk of non-compliance, ensuring smooth operations and customer trust in their chemical products.

Tutorials & Guides

We offer a variety of resources to help you get the most out of SigzenCHEM:

Frequently Asked Questions

How does SigzenCHEM optimize batch production?

SigzenCHEM uses advanced MRP, optimized scheduling, and batch optimization tools to minimize waste, reduce production costs, and ensure that chemical production schedules are met on time with higher throughput.

Can SigzenCHEM help with regulatory compliance?

Yes, SigzenCHEM provides built-in tools for generating compliance reports (e.g., related to safety data sheets, environmental regulations) and staying up-to-date with regulatory changes, ensuring that your business remains compliant with safety and environmental regulations.

How does SigzenCHEM handle formulation adjustments?

SigzenCHEM allows you to make formula adjustments to improve product quality or production efficiency using version control, while maintaining the confidentiality of proprietary chemical formulations through robust access controls.

What inventory management features does SigzenCHEM offer?

SigzenCHEM offers batch-wise inventory tracking with full traceability, auto-reordering based on consumption or safety stock, and accurate cost accounting including by-product and waste valuation, ensuring that your chemical inventory is optimized for production needs.

Can SigzenCHEM be integrated with other ERPNext modules?

Yes, SigzenCHEM integrates natively with core ERPNext modules such as Accounting, HR, CRM, Sales, Purchase, and Inventory, providing a unified platform for managing all aspects of your chemical business.

What is the typical implementation timeline for SigzenCHEM, and what support is included?

The implementation timeline for SigzenCHEM chemical ERP varies based on your specific requirements and complexity, typically ranging from 3 to 6 months for standard setups. As a certified ERPNext partner based in Ahmedabad, we follow a structured, phased approach. Our implementation support includes configuration, data migration, comprehensive user training, and dedicated post-go-live assistance to ensure a smooth transition for your chemical manufacturing business.

How does SigzenCHEM protect the confidentiality of sensitive chemical formulations and R&D data?

SigzenCHEM prioritizes formulation confidentiality and chemical data security. Access to sensitive formulation data is restricted through robust role-based access controls within ERPNext. The secure chemical ERP platform utilizes industry-standard security protocols, and detailed audit trails log user activity, ensuring your proprietary information and R&D data remain protected within the system.

How comprehensive is the batch and lot traceability within SigzenCHEM for chemical products?

SigzenCHEM provides comprehensive end-to-end traceability. Our batch traceability chemical ERP features allow tracking from incoming raw material lots, through multi-stage production processes and quality checks, to finished goods batches shipped to customers. This ensures full chemical supply chain visibility and helps meet stringent regulatory (like GHS) and quality requirements.

Is SigzenCHEM scalable for both small specialty chemical producers and large manufacturing plants?

Absolutely. Built on the flexible and open-source ERPNext platform, SigzenCHEM is highly scalable. Its modular design allows it to cater effectively to the needs of both small specialty chemical businesses and large chemical manufacturing plants. The scalable chemical ERP grows with your business, accommodating increased users, transaction volumes, and operational complexity seamlessly.

Start Your Chemical ERP Journey with a Free Consultation

Transform your chemical manufacturing operations with SigzenCHEM. Contact us today (Sigzen Technologies, Ahmedabad) for a free demo and discover how our solution can help you improve batch production, ensure regulatory compliance, and reduce costs.

Trust Elements

”SigzenCHEM has transformed the way we manage batch production at Paragon Fine and Speciality Chemical Limited. We've reduced waste and improved product quality significantly.

Rutesh SavaliyaParagon Fine and Speciality Chemical Limited.

”The regulatory compliance tools in SigzenCHEM are a lifesaver. We can now generate reports quickly and stay compliant with industry regulations at Rasayan Biotech.

Hiren bhaiRasayan Biotech

” The regulatory compliance tools in SigzenCHEM are a lifesaver. We can now generate reports quickly and stay compliant with industry regulations at Rasayan Biotech.

Hiren bhaiRasayan Biotech

” SigzenCHEM has transformed the way we manage batch production at Paragon Fine and Speciality Chemical Limited. We've reduced waste and improved product quality significantly.

Rutesh SavaliyaParagon Fine and Speciality Chemical Limited.