The Manufacturing Module in ERPNext is designed to streamline and automate all aspects of the manufacturing process, ensuring efficiency, cost control, and real-time tracking. This comprehensive manufacturing ERP solution enables manufacturers to manage production, resources, and inventory with precision and ease. From production planning and scheduling to quality control, the Manufacturing Module integrates all critical manufacturing processes into one unified system, providing a complete overview of operations. Whether your manufacturing setup is small-scale or a large enterprise, ERPNext’s Manufacturing Module helps optimize production workflows, reduce wastage, and improve overall productivity and profitability.

Key Features

Integration

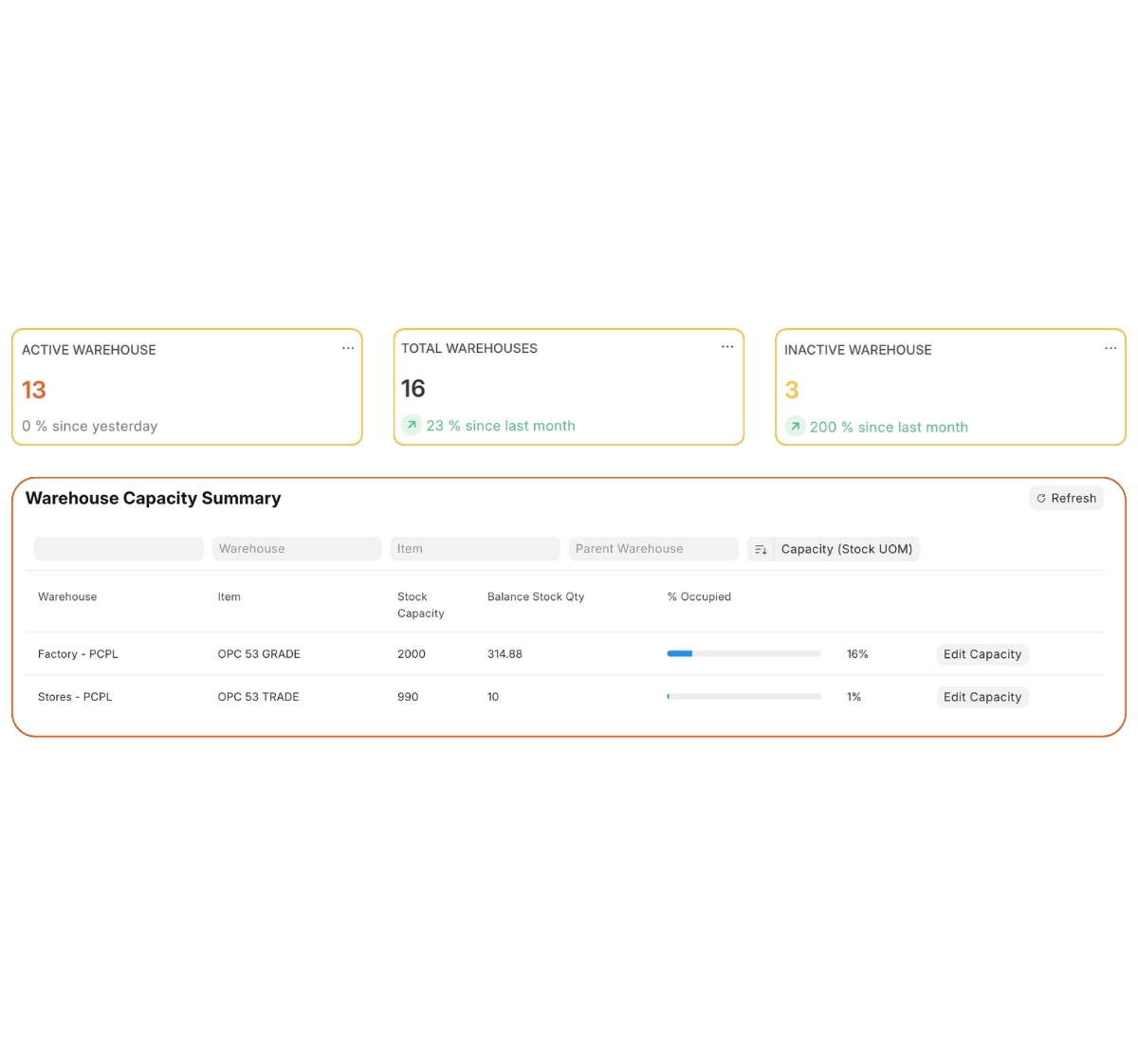

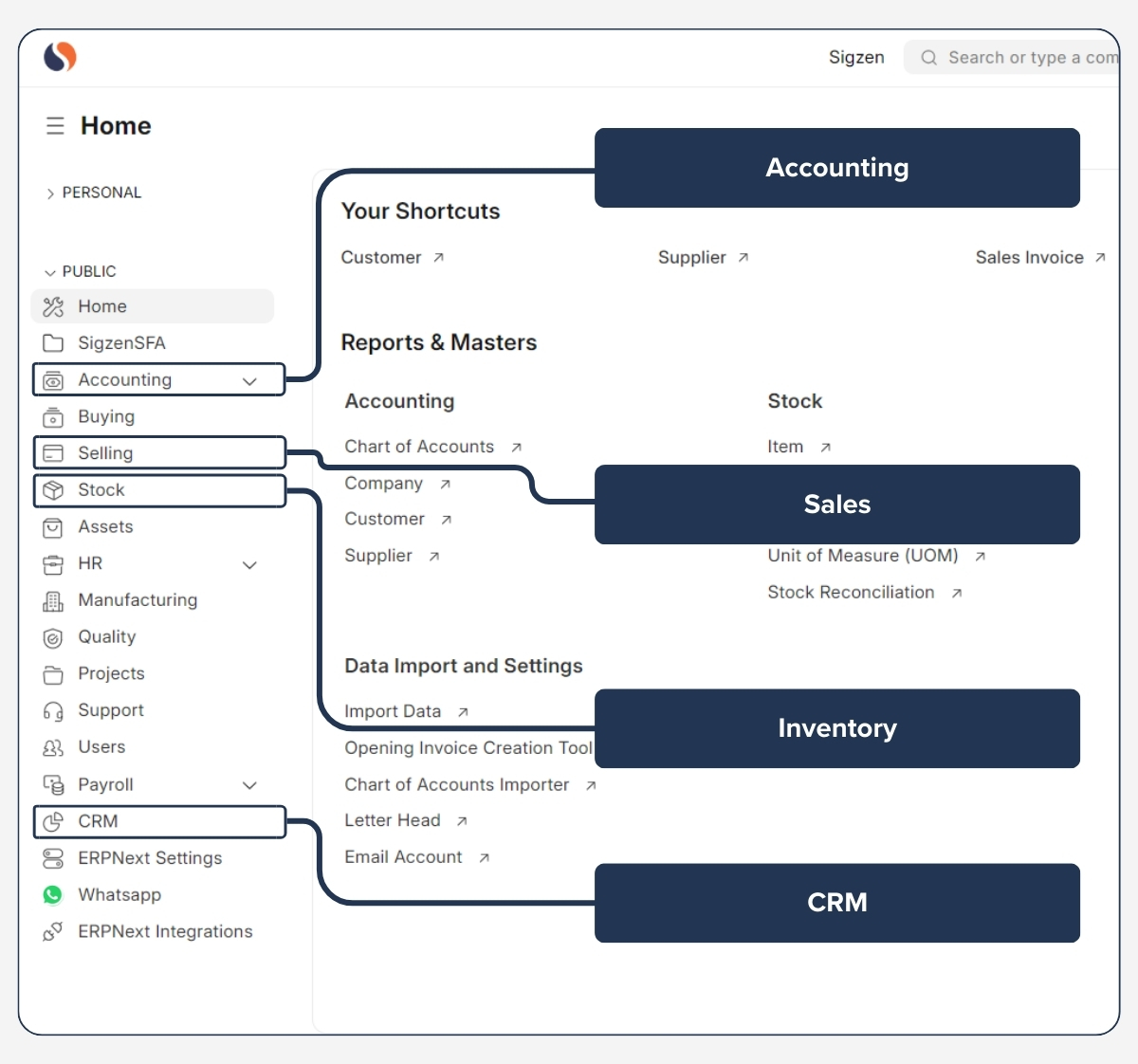

The Manufacturing Module integrates seamlessly with other core ERPNext modules, such as Accounting, CRM, Inventory, and Sales, to provide a complete business management solution. For example, work orders can automatically trigger accounting entries for costing, while production planning can factor in sales forecasts from the CRM module. Integration with third-party applications, including machine automation tools (IIoT) and advanced warehouse management systems (WMS), is also supported through REST APIs. This ensures that all aspects of manufacturing, from procurement and production to delivery, are managed efficiently within one unified system.

Case Studies

1. Streamlining Production for an Electronics Manufacturer

Challenge

An electronics manufacturer struggled with manual production tracking, leading to delays and resource mismanagement.

Solution

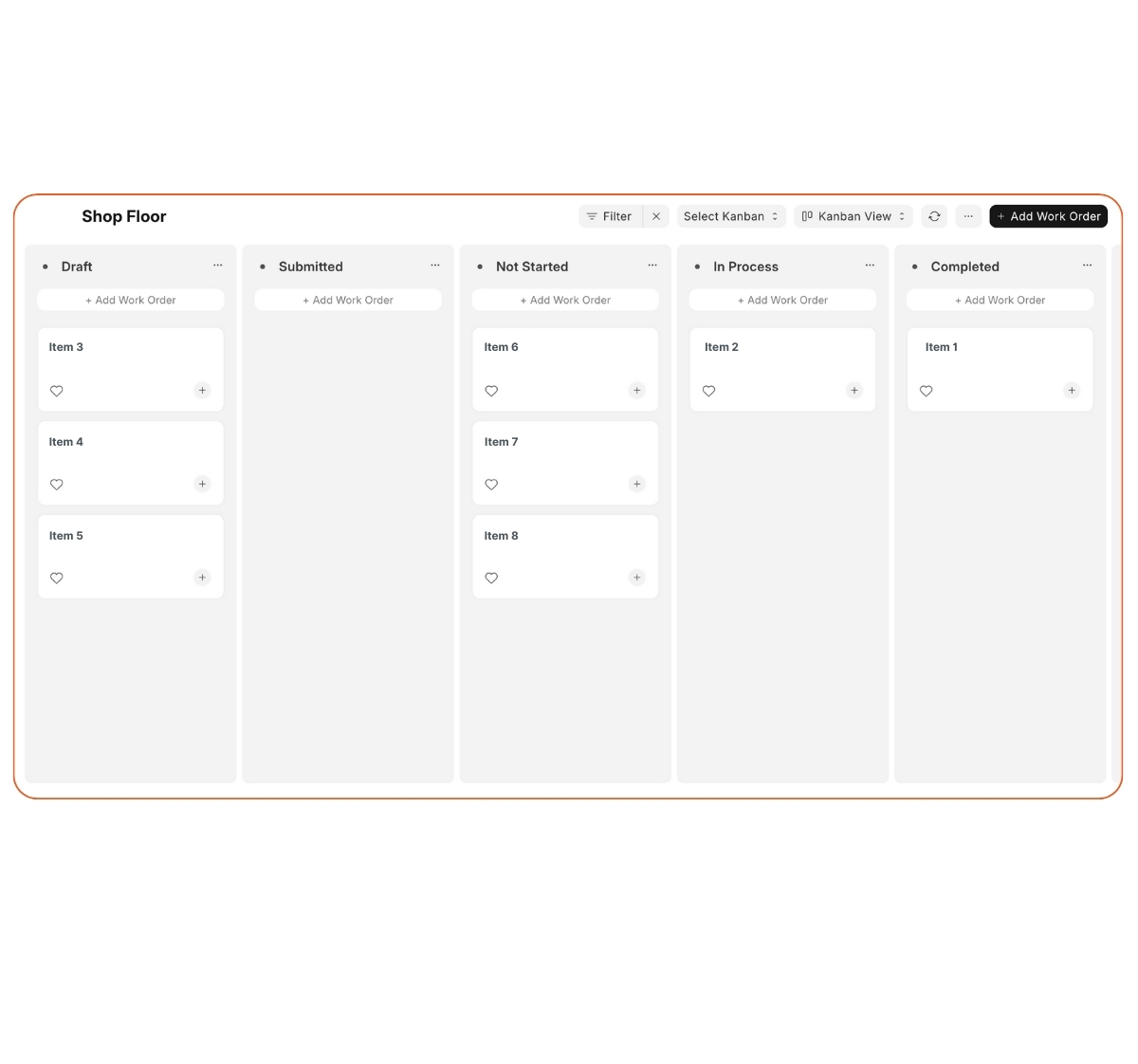

By implementing ERPNext’s Manufacturing Module, they automated production planning, shop floor control, material requirements planning (MRP), and quality management.

Results

The company achieved a 25% increase in production efficiency and reduced operational costs by 15%.

2. Improving Material Planning for a Furniture Manufacturer

Challenge

A mid-sized furniture manufacturer faced frequent material shortages and production delays.

Solution

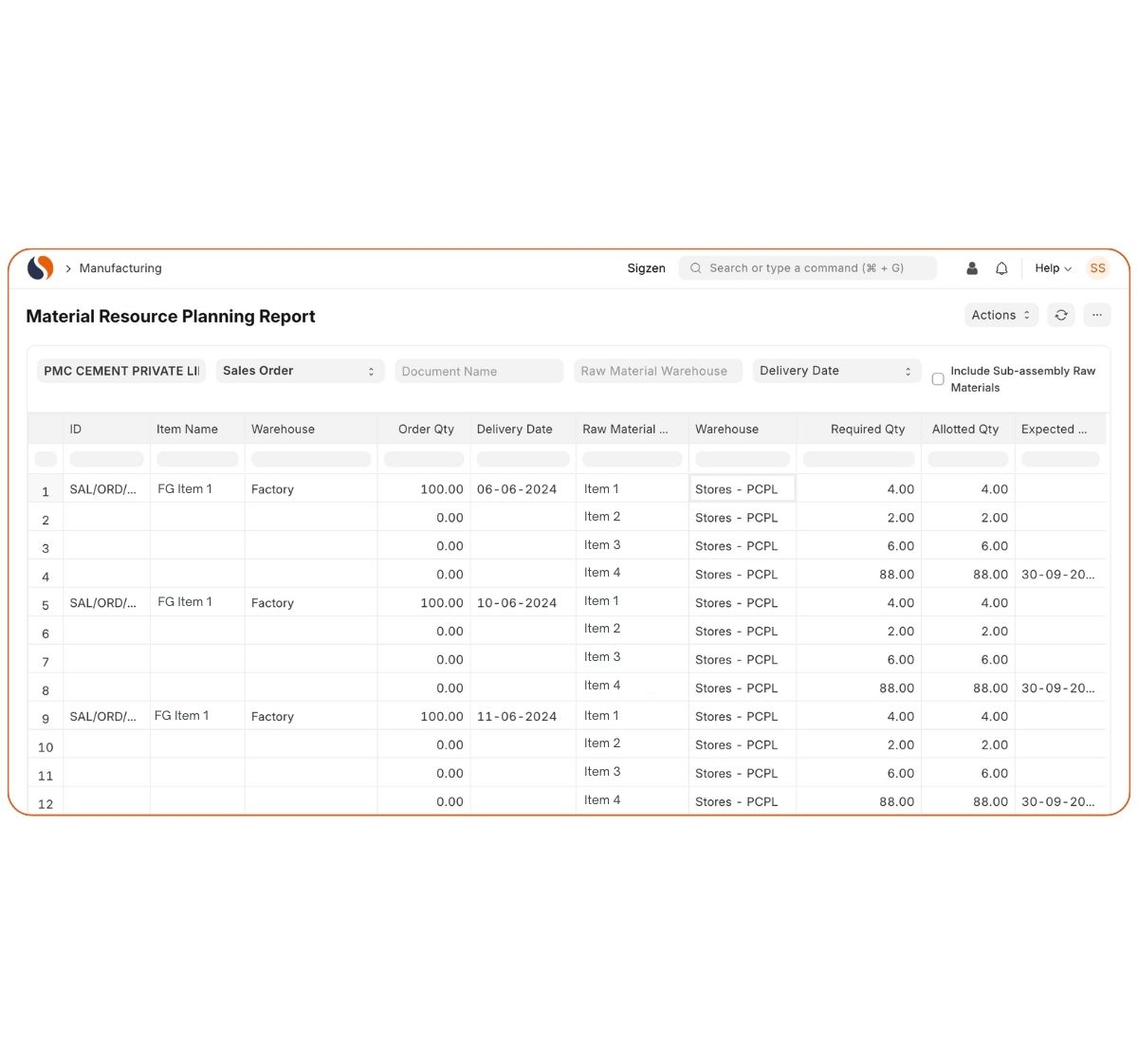

The Manufacturing Module’s Material Requirement Planning (MRP) feature enabled real-time material tracking and automated procurement suggestions.

Results

The company saw a 30% reduction in material shortages and a 20% improvement in on-time delivery rates.

Tutorials & Guides

To help users maximize the potential of the ERPNext Manufacturing Module, ERPNext offers a variety of support resources:

Frequently Asked Questions

How does the Manufacturing Module help with production planning?

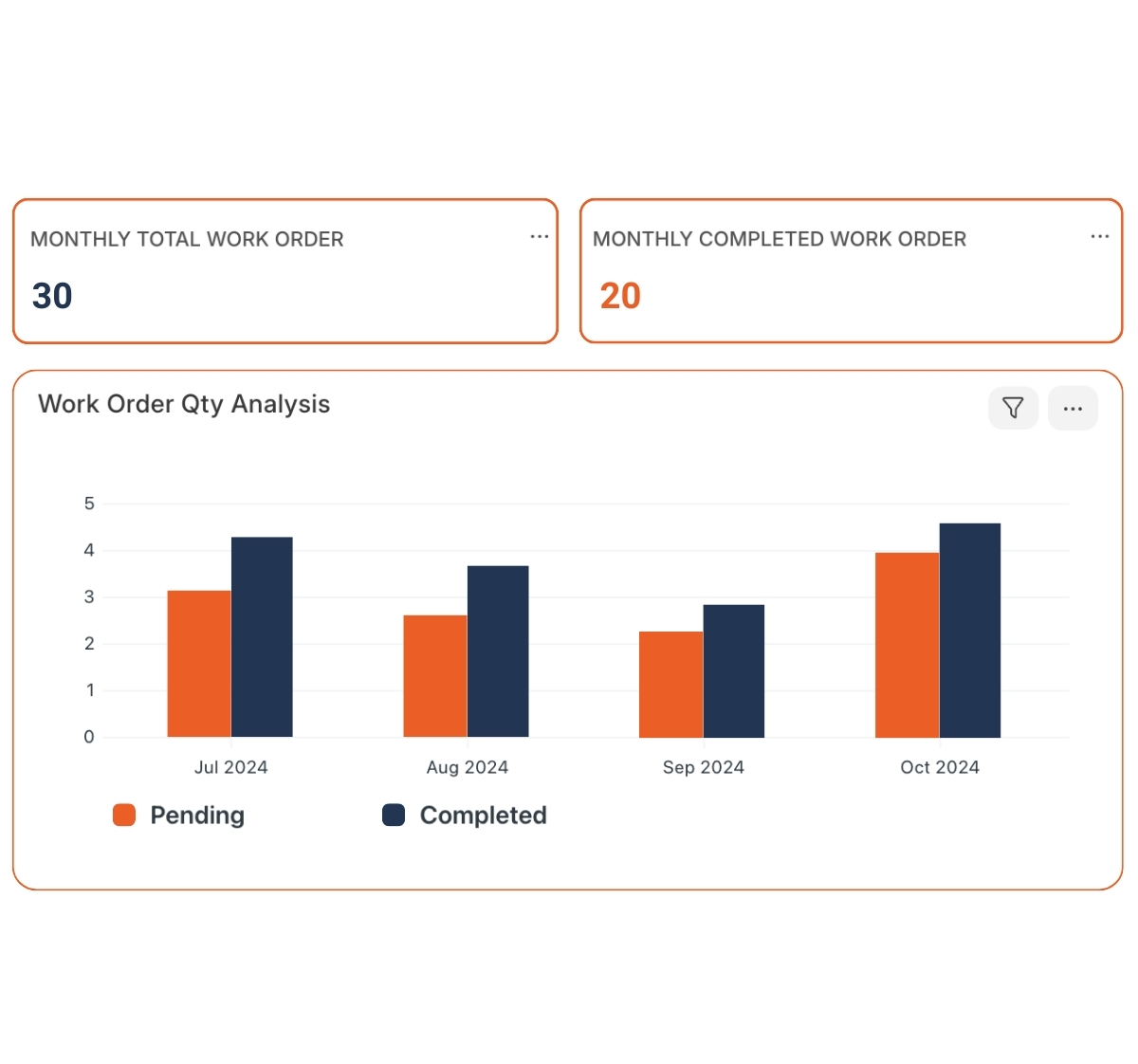

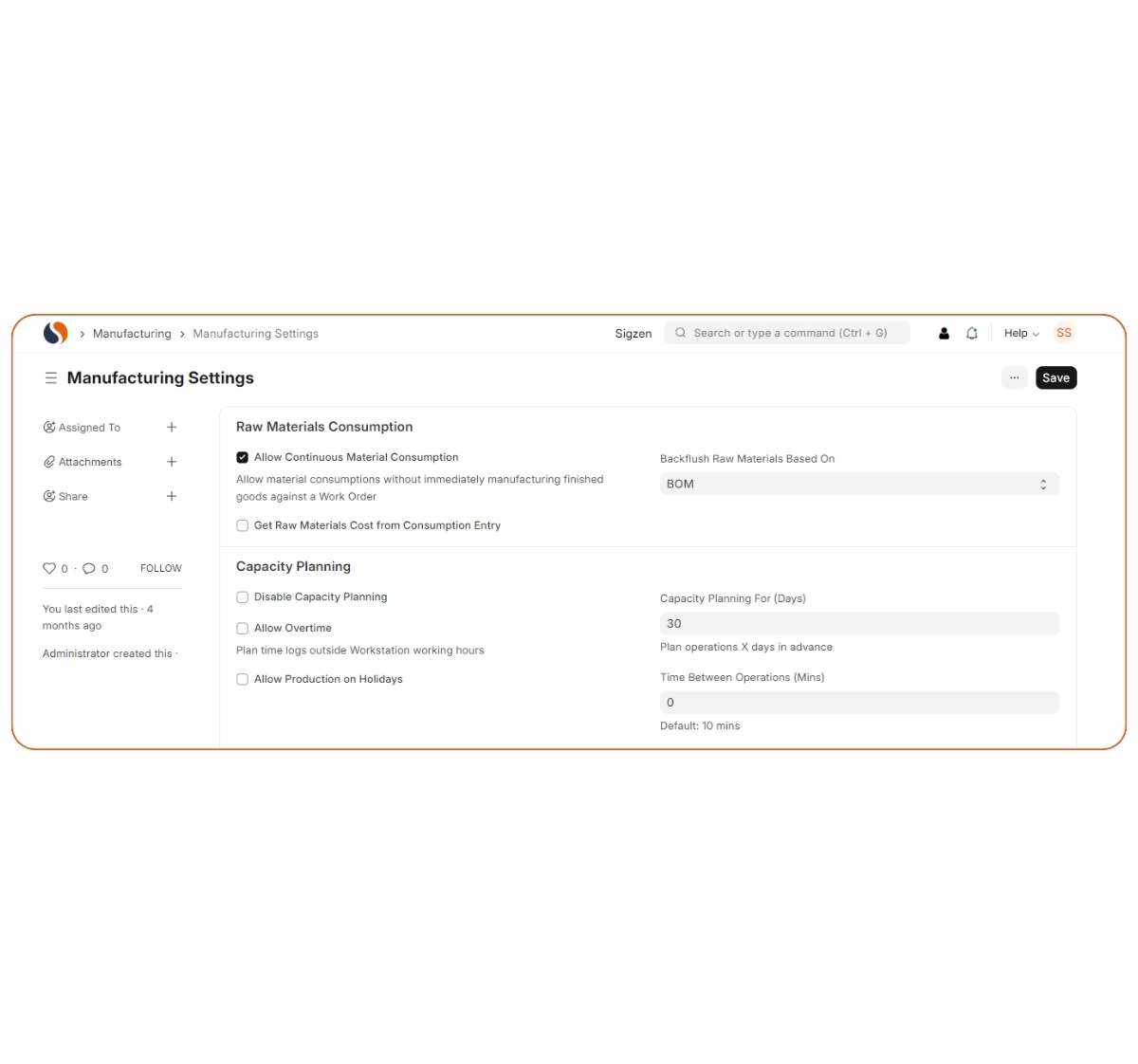

The Manufacturing Module offers automated production planning, scheduling, capacity analysis, and real-time tracking, ensuring that resources are allocated efficiently and orders are fulfilled on time based on demand.

Can the Manufacturing Module handle subcontracting?

Yes, ERPNext’s Manufacturing Module supports subcontracting by tracking materials sent to subcontractors, managing subcontractor operations, and managing the receipt of finished goods back into inventory.

How does the module integrate with other ERPNext features?

The Manufacturing Module integrates natively with modules like Accounting, Inventory, CRM, and Sales, ensuring seamless flow of data across the business for unified operations management.

What production planning types are supported?

The Manufacturing Module supports Make-to-Stock (MTS), Make-to-Order (MTO), and Engineer-to-Order (ETO) planning models, giving manufacturers flexibility in their operations and business strategies.

Can we track semi-finished goods?

Yes, you can track semi-finished goods (Work-in-Progress) at various stages of production, ensuring that all components are accounted for during the production process and WIP valuation is accurate.

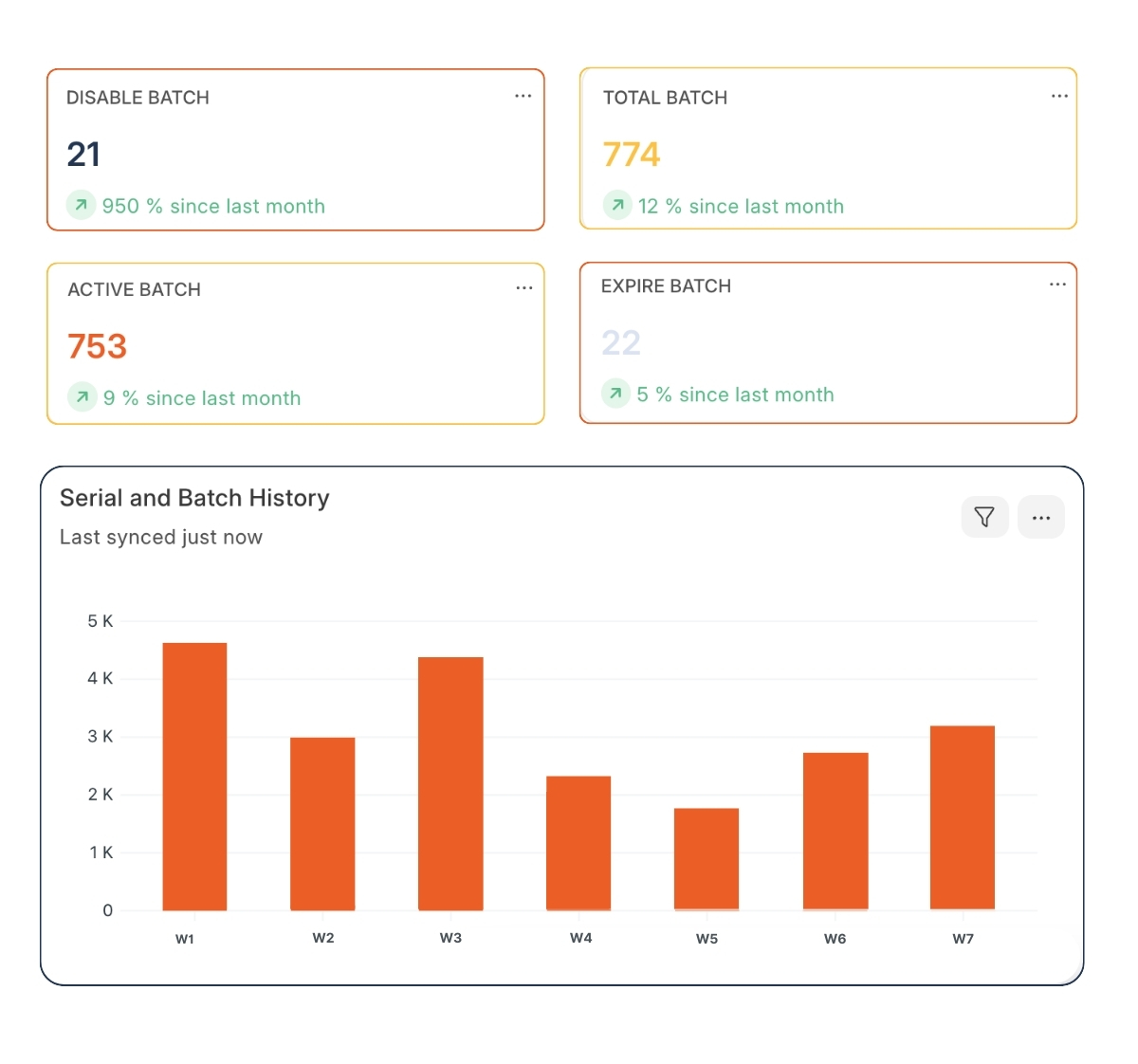

Does the module support batch and serial number tracking?

Yes, the Manufacturing Module allows for batch and serial number tracking, which is essential for inventory management, quality control, regulatory compliance, and product traceability.

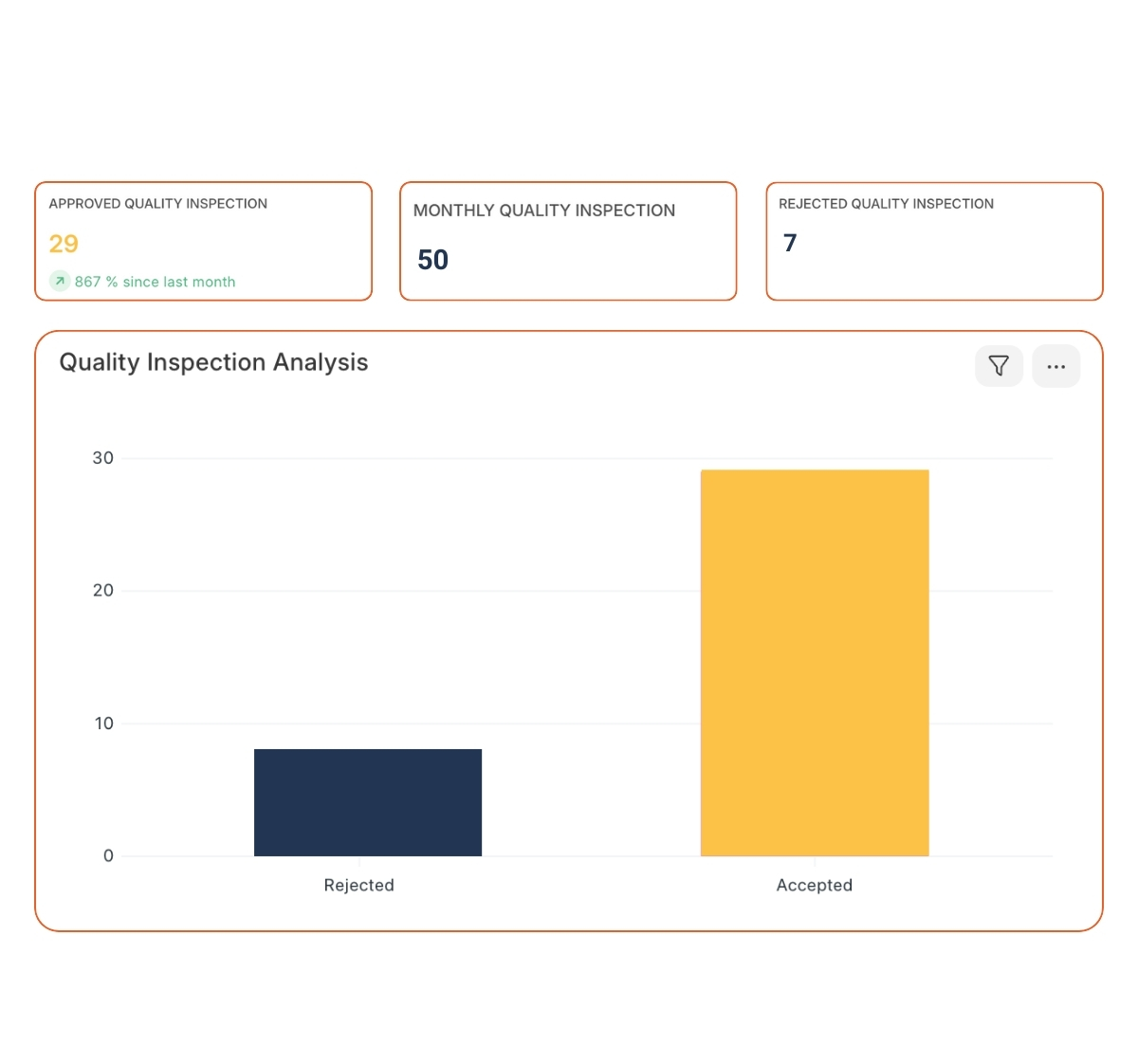

How does the module handle quality control?

The Manufacturing Module includes quality control features that enable defining QC parameters and conducting inspections at different stages of production, helping to maintain product standards and reduce defects systematically.

Get a free no obligation quote now

Maximize your manufacturing efficiency with ERPNext’s Manufacturing Module. Contact us today to schedule a demo and see how our ERP solutions can transform your production workflows, reduce costs, and improve your bottom line. Let Sigzen Technologies Pvt. Ltd. guide you through a seamless ERP implementation for your factory.

Trust Elements

” Implementing ERPNext’s Manufacturing module has been a game-changer for our production process. It integrates production planning, inventory tracking and quality control seamlessly, giving us clear visibility at every stage. With its user-friendly interface and powerful features, we’ve reduced downtime, optimized resources and scaled efficiently allowing us to focus on growth and consistently deliver high-quality products.

Mr. BhattGM Plant - Unity Cement

” The Manufacturing Module in ERPNext has completely revolutionized our production process. We now have real-time tracking, which helps us stay ahead of our deadlines.

Bhavesh PatelMD, Rachna Bio Chemtech

” The integration with inventory and sales has helped us streamline our entire operation, from raw material procurement to finished goods dispatch.

Shivam PatelDirector, Paragon Fine and Speciality Chemicals Ltd

Download ERPNext Mobile App

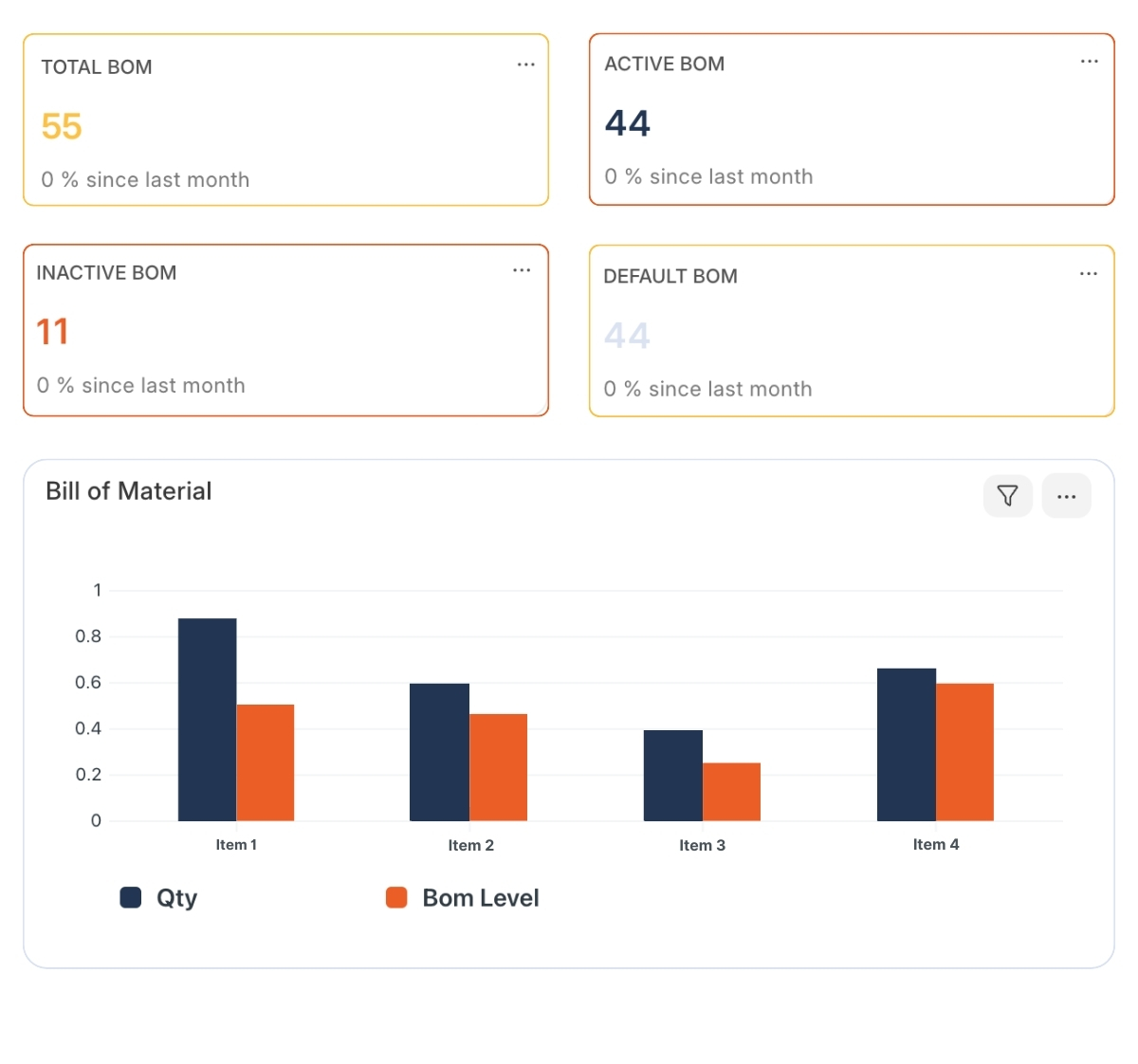

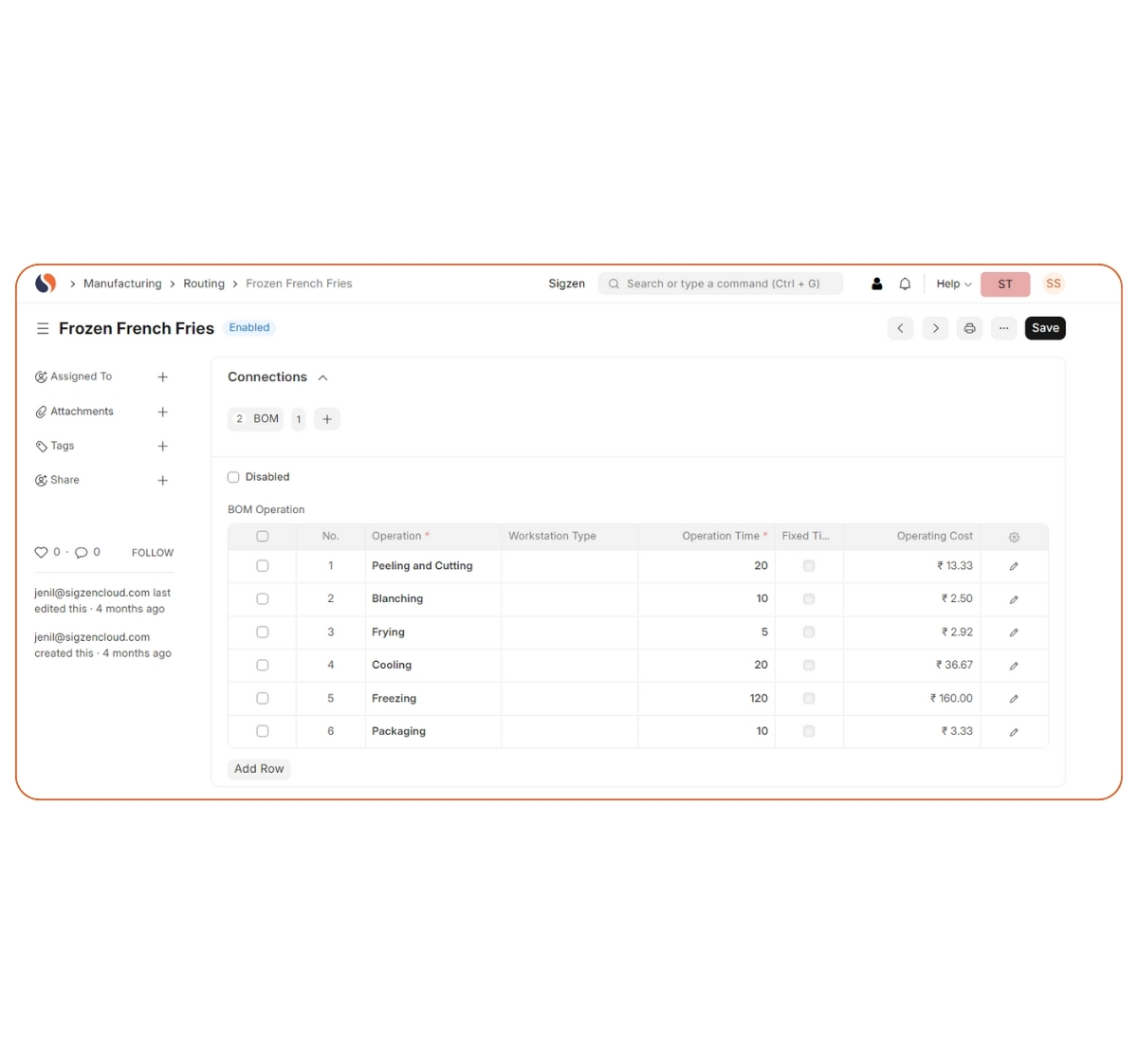

Manage end-to-end manufacturing operations including work orders, BOMs, job cards, capacity planning, and production tracking. ERPNext ensures optimized resource utilization, reduced wastage, real-time shop-floor visibility, and improved production efficiency.